By 2025, Dongfeng's IGBT and SiC projects could produce about 1.2 million power modules per year, it said.

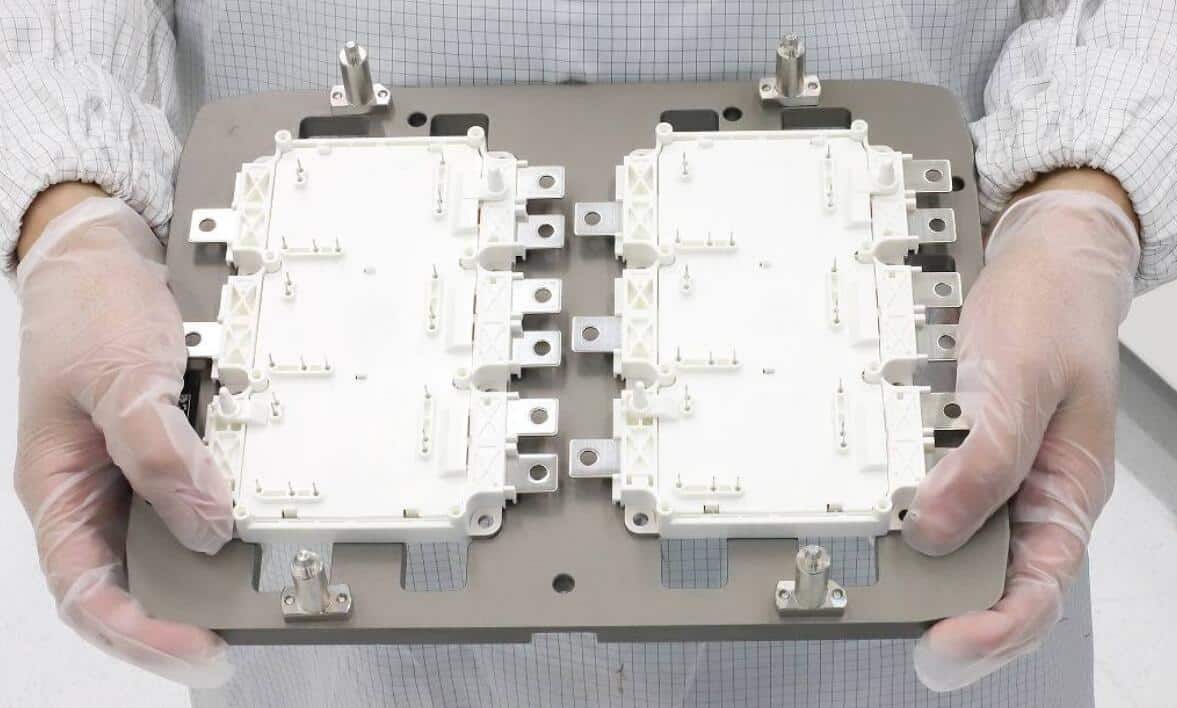

(Image shows Dongfeng Motor's IGBT module. Credit: Dongfeng)

Chinese automotive giant Dongfeng Motor is building its own next-generation power semiconductors, becoming the latest local automaker to undertake such an effort.

Dongfeng launched a silicon carbide (SiC) power module manufacturing project in January 2021, and the modules will be mass-produced in 2023 and be loaded in the company's new energy passenger cars, it announced on Monday.

SiC modules are an upgrade to IGBT (insulated gate bipolar transistor chip) modules, a third-generation power semiconductor with higher efficiency, high-temperature resistance and high-voltage characteristics, a Dongfeng article reads.

The modules will help upgrade the electrical architecture of new energy vehicles (NEVs) from 400V to 800V, allowing them to charge from 0 to 80 percent in just 10 minutes, Dongfeng said.

The SiC modules can also improve the range of NEVs and reduce vehicle costs, the company said.

This is Dongfeng's latest effort to produce its own power semiconductor modules. In July 2021, the company announced that its production line with an annual capacity of 300,000 IGBT modules went into operation at its NEV industrial park in Wuhan.

The production line is the first phase of Dongfeng's project, and its second phase, with a total investment of 280 million yuan ($40.32 million), is also moving forward, the company said Monday.

The new project will optimize the existing production line to increase production of IGBT power modules and will also see the establishment of two brand new production lines to produce IGBT modules and SiC modules, respectively, it said.

By 2025, the projects could produce about 1.2 million power modules per year, Dongfeng said.

In addition to IGBT modules and SiC modules, Dongfeng is also getting into MCU chips.

The company will work with China Information and Communication Technology Group to establish a joint lab for automotive chips.

The two will push for automotive MCU chips to be produced in Wuhan, with mass production expected in 2024, Dongfeng said.

Dongfeng has also worked with local chip foundry SMIC to complete the design of the company's first MCU chip, the company said.

Mainstream carmakers still use IGBTs, but Tesla, BYD, Nio and other carmakers have started using SiC chips.

Nio announced on June 22, 2021 that the first SiC electric drive system C prototype for the ET7 rolled off the production line. The CEO of the company's motor division said at the time that SiC is more resistant to high temperatures and has significantly lower overall losses compared to IGBT modules, helping to improve range.

On August 24 this year, Li Auto's power semiconductor R&D and production base officially started construction in Suzhou, Jiangsu province, focusing mainly on the development and production of SiC modules.

On February 16, SiC chip startup InventChip Technology announced that it had closed a strategic financing round with exclusive participation from Xpeng.