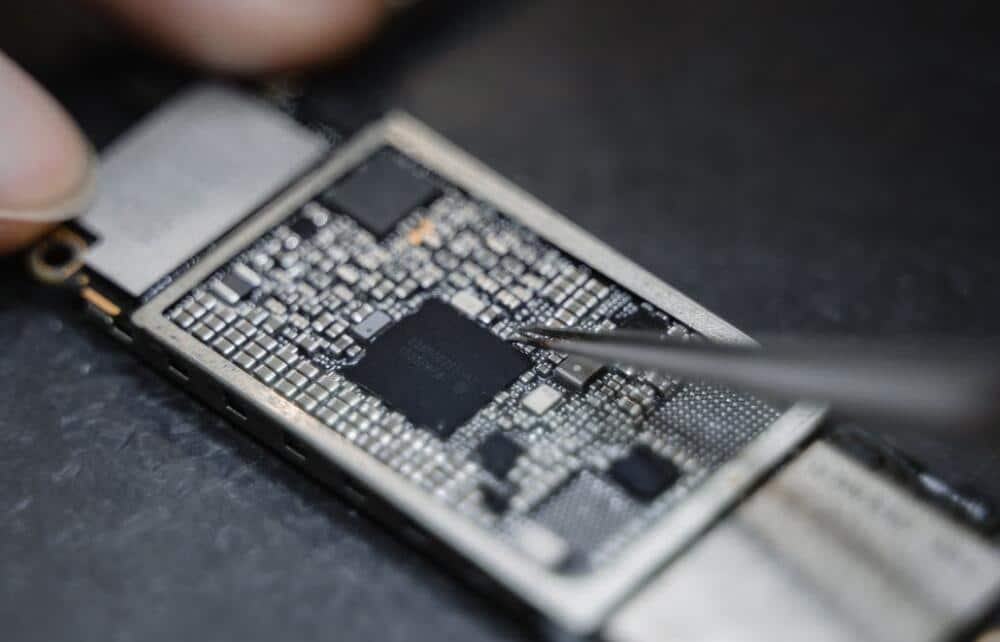

Good news for the global automotive industry hit by a global chip shortage.

Japan's Renesas Electronics Corp said Friday that as of the evening of June 24, production capacity at the N3 Building of Naka Factory, which was damaged by a fire in March, had returned to 100 percent of pre-accident levels.

In addition, alternative production is contributing to Renesas’ manufacturing as planned, the company said.

The shipment level of the products manufactured in the N3 Building is expected to return to pre-fire level around the third week of July, it said.

However, this shipment level refers to that of the N3 Building as a whole. Therefore, the recovery timing of the shipment level may vary from product to product, it added.

Renesas will continue its efforts for production safety, and with the cooperation of the fire department, the police and other relevant authorities, the company will work to prevent accidents such as fires from happening again, it said.

Renesas has nearly a third of the global market share in automotive microcontroller chips, and the fire has hit global automotive production hard.

In late March, Renesas said the fire had caused more damage than expected, and on April 17, the company said the plant was back in operation.

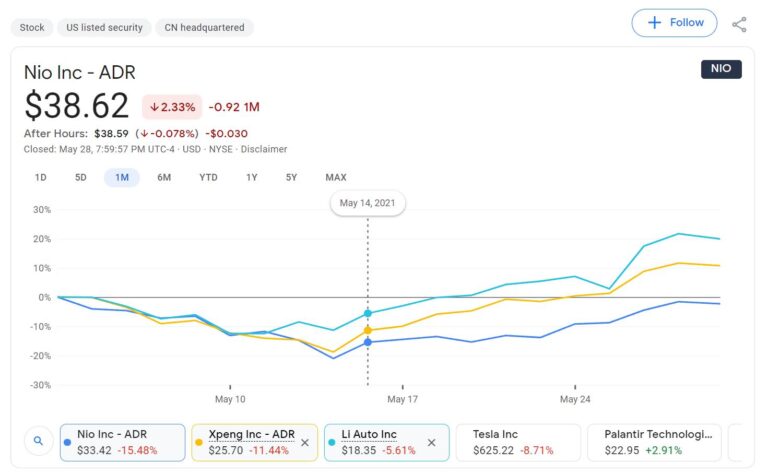

At one point, Ford, GM, Hyundai and Kia were forced to shut down production for days or even weeks due to chip shortages. Chinese electric car company Nio had also stopped production for five working days from late March to early April.

In order to ensure the supply of chips, Tesla was reportedly considering the use of early payment to seize chip capacity, and even consider buying chip factories.

In fact, while car companies still expect chip shortages to be unresolved in the short term, analysts have recently begun to expect marginal improvements in the situation to begin to emerge.

In a research report late last month, top Chinese investment bank CICC said that chip supply bottlenecks dragging down sales performance and earnings pressure due to raw material price hikes are two of the core concerns investors have about the auto industry.

However, the good news is that the team believes that moving forward, these two major concerns are improving at the margin, and the share price pullback has priced in the pressure on auto company performance.

In terms of chip supply, CICC expects it to have an impact on Q2 sales of around 200,000 units, less than 1Q, signaling a marginal improvement in the impact of the chip issue.

On June 22, CICC said the impact of the chip shortage continues, resulting in relatively flat production and sales in the first half of June.

The chip shortage is expected to ease within the Chinese auto industry in the second half of the year, and the industry will gradually enter an inventory-raising cycle, the CICC said.