The Bedrock Chassis takes smart chassis safety to new heights and promises to accelerate the shift towards modular and personalized vehicle design.

Contemporary Amperex Technology Co Ltd (CATL, SHE: 300750) has unveiled a skateboard chassis called the Bedrock Chassis, which emphasizes safety and envisions a future in which exterior design is highly customizable by customers.

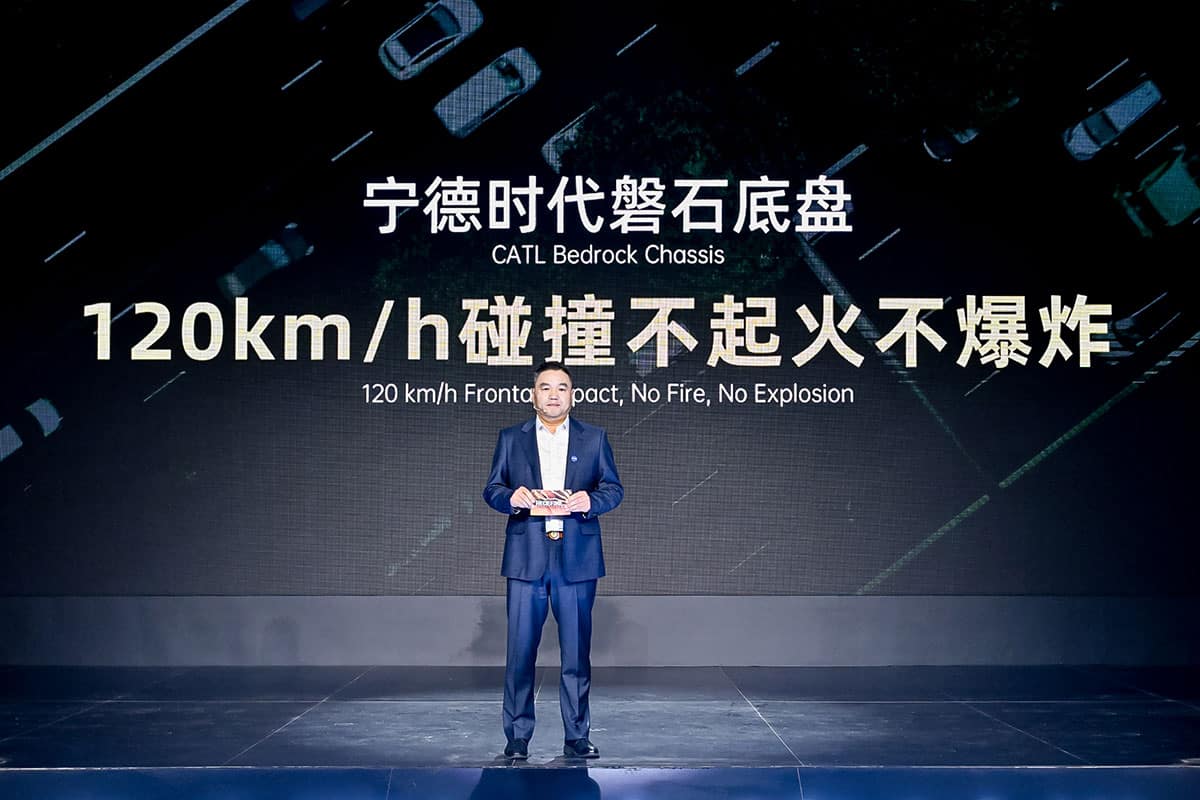

The Chinese power battery giant introduced the Bedrock Chassis at an in Shanghai today, calling it the world's first ultra-safe skateboard chassis.

The concept of a skateboard chassis, originally released by General Motors in 2002, allows for decoupling of the upper and lower bodies and parallel development, thus shortening the development cycle.

In China, there are startups focusing on this area. CATL previously launched a skateboard chassis called CIIC (CATL Integrated Intelligent Chassis), and the Bedrock Chassis is the flagship variant of the CIIC.

The Bedrock Chassis will redefine safety standards for intelligent chassis and also activate a trillion-yuan market that will greatly accelerate the shift to modular, personalized, and intelligent vehicle design, the battery maker said at today's event.

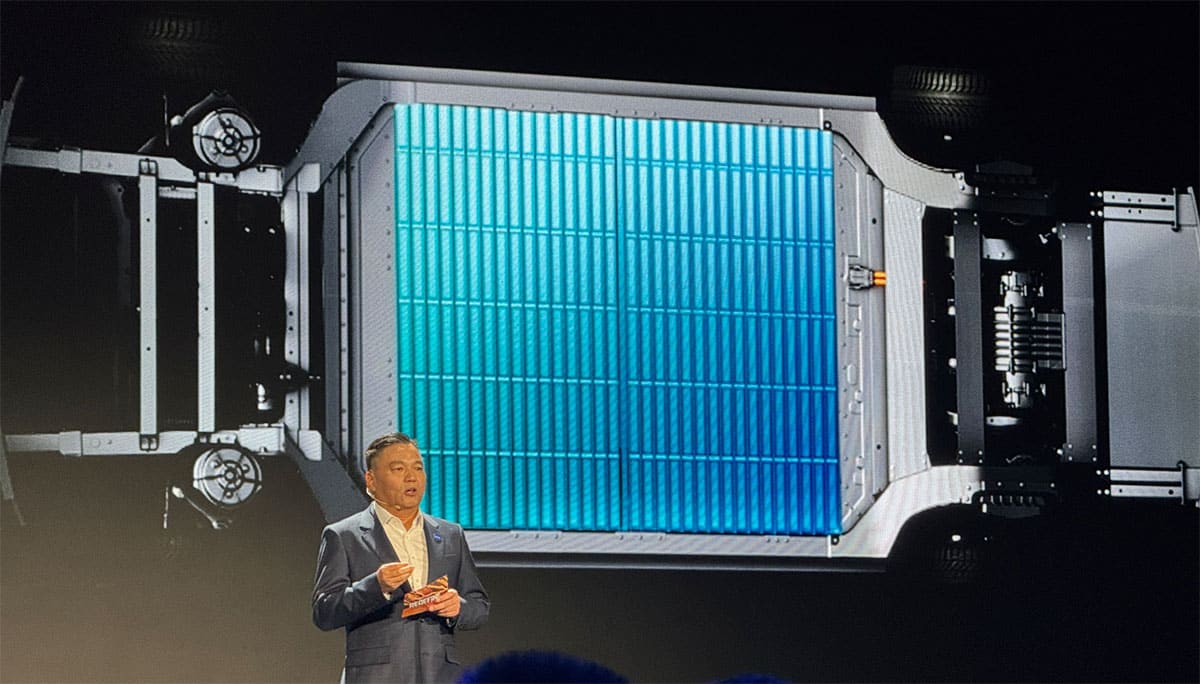

CATL highlighted the safety of the Bedrock Chassis, saying that the chassis is battery-centric and adopts cell-to-chassis integration technology, which integrates the battery cells directly into the chassis and realizes a shared structural design between them.

The chassis is capable of absorbing 85 percent of the vehicle's collision energy, much higher than the traditional chassis absorbing about 60 percent of the energy, according to the company.

CATL presented a video at today's event showing a prototype built on the Bedrock Chassis that did not catch fire, explode, or suffer thermal runaway in a 120 km/h frontal central pole impact test.

The crash energy in the test is equivalent to 4.6 times the energy produced in the commonly used C-NCAP frontal crash safety test at 56 km/h.

The Bedrock Chassis utilizes a three-dimensional bionic tortoise shell structure with the body integrated into the energy unit frame to provide protection for the energy unit.

It uses submarine-grade hot-formed steel with a strength of 2,000 MPa, aerospace-grade aluminum alloys with a strength of 600 MPa, and multiple barrier structures to further enhance chassis rigidity, according to CATL.

In terms of high-voltage disconnection, it achieves instantaneous disconnection of high-voltage circuits within 0.01 seconds after impact, and completes the residual high-voltage energy release from the vehicle within 0.2 seconds, setting a new industry record, according to the company.

Beyond high safety, the Bedrock Chassis, like the traditional skateboard chassis, can significantly improve the efficiency of new model development.

The Bedrock Chassis allows vehicle manufacturers to build multiple models based on a single chassis architecture, thereby reducing the time to mass-produce a vehicle from the traditional 36 months or longer to 12-18 months, according to CATL.

Moreover, the chassis breaks through safety and styling constraints, expanding design flexibility through a design that decouples the chassis from the upper body.

With the support of the chassis, the era of uniquely designed vehicles for everyone will soon come, said CATL.

The Bedrock Chassis also supports mechanical decoupling and software decoupling to realize L3~L4 intelligent driving capabilities.

The first automaker to adopt Bedrock Chassis is Changan Automobile's subsidiary Avatr Technology and a signing took place today.

The companies did not mention when the first Bedrock Chassis-based model will be launched.

The launch of the Bedrock Chassis is CATL's latest attempt to extend its business further upstream in the power battery sector.

The chassis, if adopted on a large scale, would mean that the battery maker's business would extend to cover a significant part of traditional car businesses.

CATL's last attempt to innovate its business came just last week, unveiling two standardized Choco-SEB battery packs on December 18, and planned to jointly launch 10 models using the packs with its partners.

The company is the world's largest maker of power batteries, with a 36.8 percent share in the January-October period, making it the only battery supplier in the world with a market share of more than 30 percent, according to South Korean market researcher SNE Research.