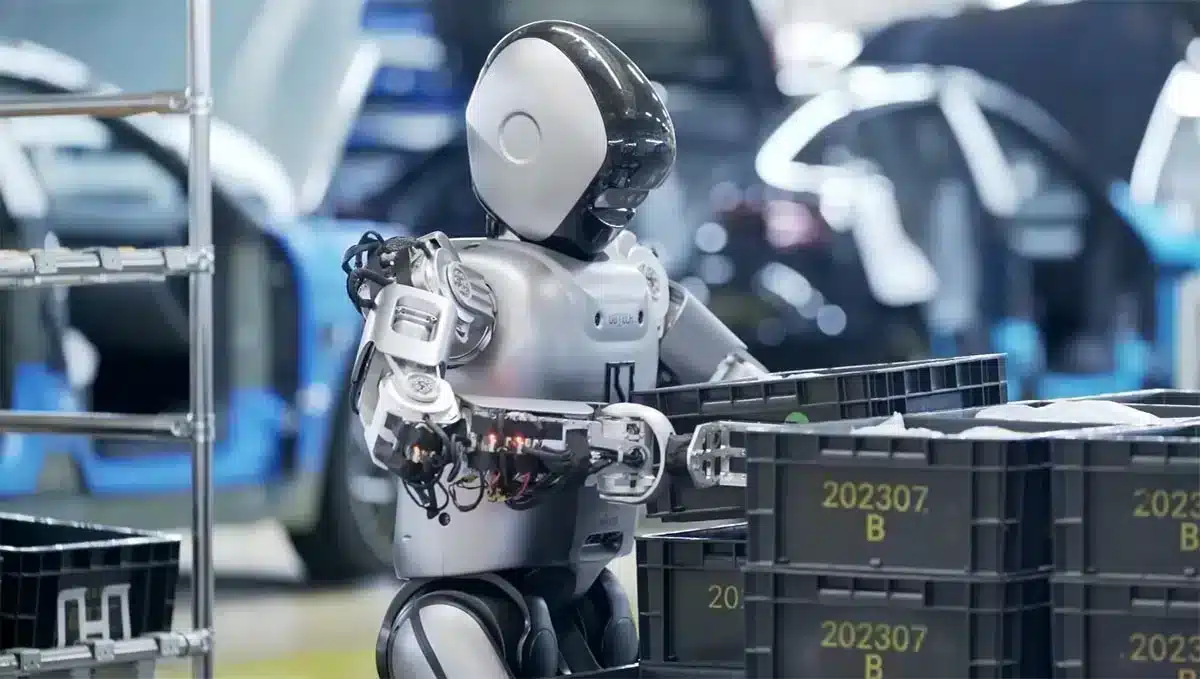

A humanoid robot supplied by UBTech has been working at a Zeekr factory for 21 consecutive days, performing tasks including lifting and carrying.

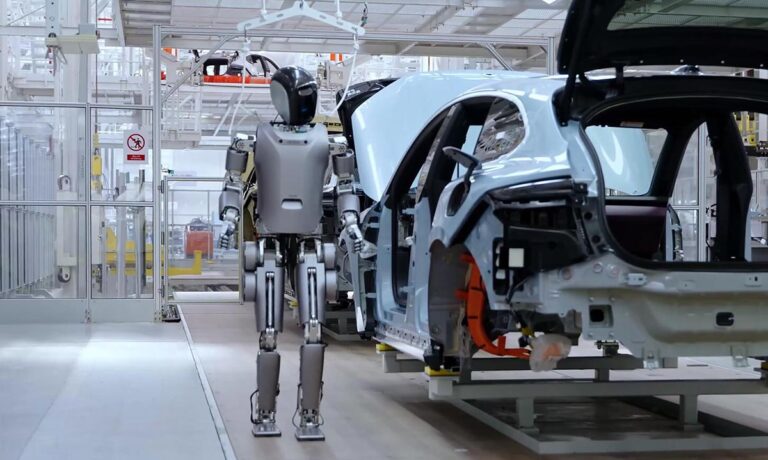

Zeekr (NYSE: ZK), the premium electric vehicle (EV) subsidiary of the Geely Holding Group, is experimenting with humanoid robot at its factory, becoming the latest automaker to do so after Nio (NYSE: NIO).

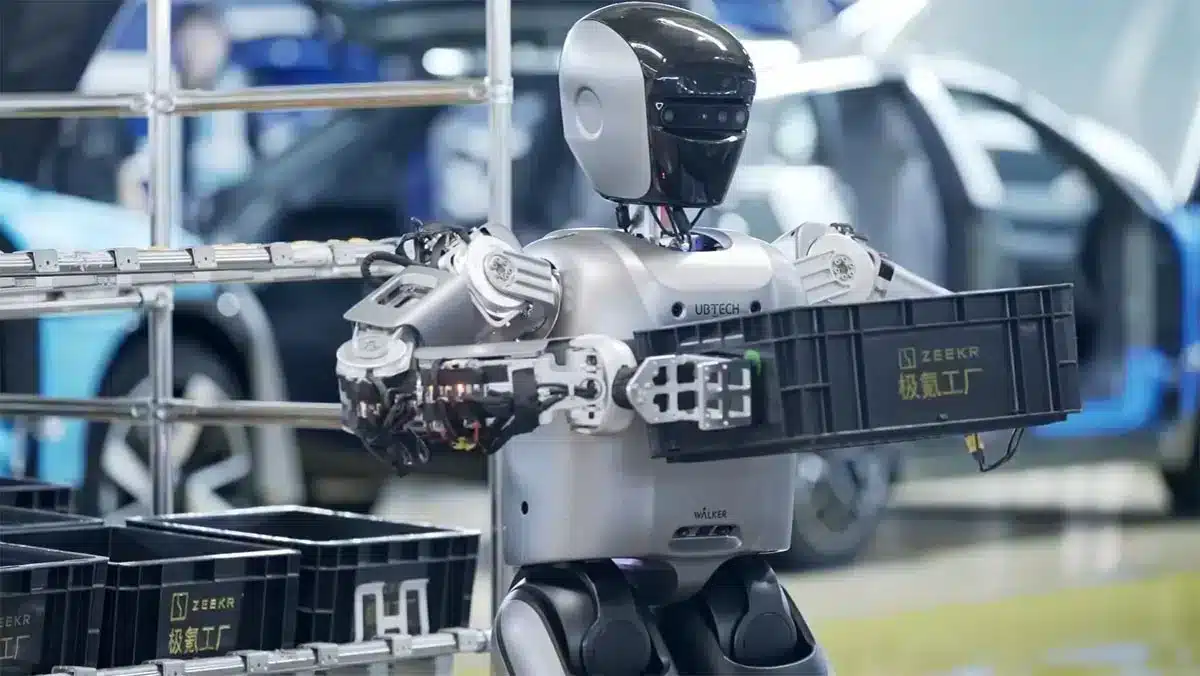

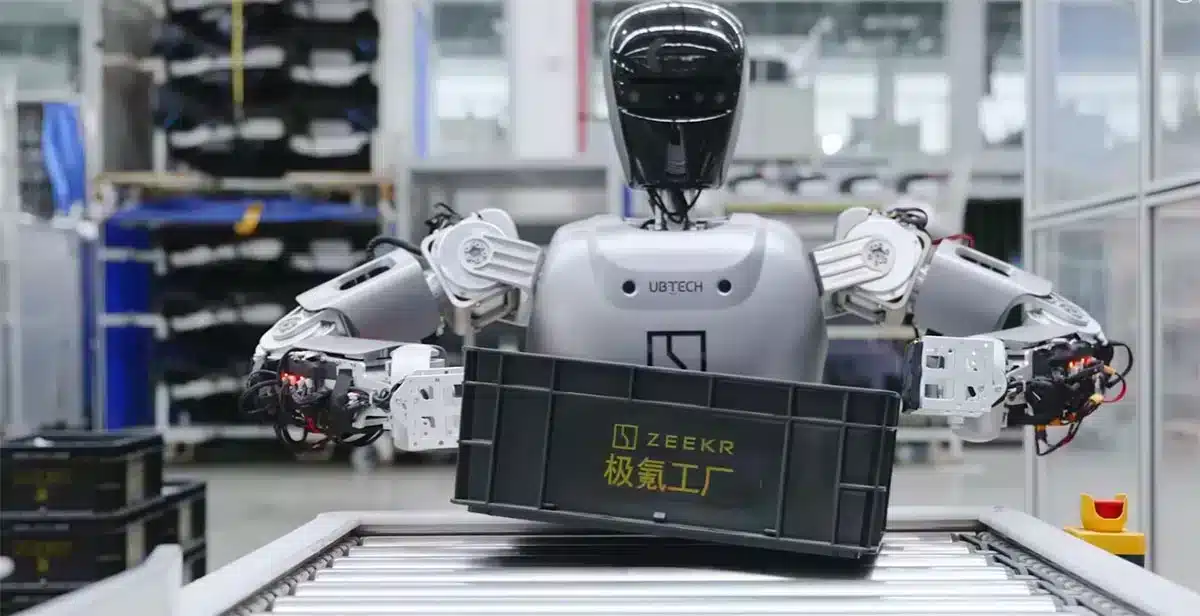

A Zeekr factory welcomed its first humanoid robot in early July, a Walker S Lite from humanoid robot maker UBTech Robotics (HKG: 9880), according to a press release by UBTech today.

As of today, Walker S Lite -- UBTech's new lightweight product for the smart manufacturing and smart logistics sectors -- has been working at the Zeekr factory for 21 consecutive days, according to the release.

The humanoid robot helped employees with lifting tasks, and its job completion and execution difficulty were among the top in the industry, UBTech said.

The humanoid robot's operation at the Zeekr plant is the result of a partnership between UBTech, Geely Holding, and Miracle Automation Engineering, according to the release.

Miracle Automation, a provider of automated logistics systems, announced on August 2 that it had won a bid for an assembly mainline conveyor project at Nio's F3-1 project, a deepening of the partnership between the two following a project at Nio's F4 plant.

Geely will provide application scenarios for UBTech's Walker S series products and solutions, and Miracle Automation will provide production line data collection, process development and scenario improvement design for humanoid robot training, according to the release.

The three parties will then work together to drive the scaling of humanoid robots for automotive and component smart manufacturing scenarios, UBTech said.

During the three-week-long on-site training, Walker S Lite combines semantic Visual Simultaneous Localization and Mapping (VSLAM) navigation, end-to-end imitation learning, visual recognition, and whole-body fine motion control to autonomously navigate and walk under load on different assembly lines and work in concert with automated guided vehicles (AGVs), according to the company.

The Walker S Lite, equipped with high-performance servo drives and six-dimensional force sensors, can walk stably while lifting 15-kilogram boxes, according to UBTech.

Zeekr is the latest EV maker to experiment with humanoid robots in factories, which is poised to further automate already high production lines.

On February 22, UBTech shared a video on Weibo showing its Walker S robot working on an assembly line at a Nio factory.

This was the first time Walker S had on-site training at a new energy vehicle (NEV) factory, UBTech said at the time.

At Nio's plant, the Walker S utilized its real-time image capture and transmission capabilities to participate in quality inspections of door locks, seat belts, headlight covers, and was able to affix vehicle logos, according to the video.

In early 2024, UBTech's humanoid robot Walker S entered Nio's F2 plant for field training, followed by partnerships with Dongfeng Liuzhou Automobile, FAW-Volkswagen Qingdao, and Geely Auto, the humanoid robotics maker said in today's press release.

UBTech is working with these partners to build humanoid robot demonstration lines and factories to use humanoid robots in typical manufacturing scenarios, it said.