RoboSense unveiled the product called RS-LiDAR-E1, its first all-solid-state LiDAR, becoming another player in the field.

(Image credit: RoboSense)

BYD-backed RoboSense showed off its technological muscle at its Tech Day event, unveiling its first all-solid-state LiDAR, a lab dedicated to LiDAR testing, and a joint venture with an electronics giant.

At the event on Monday, RoboSense officially unveiled the product, called RS-LiDAR-E1, its first all-solid-state LiDAR, becoming another player in the field.

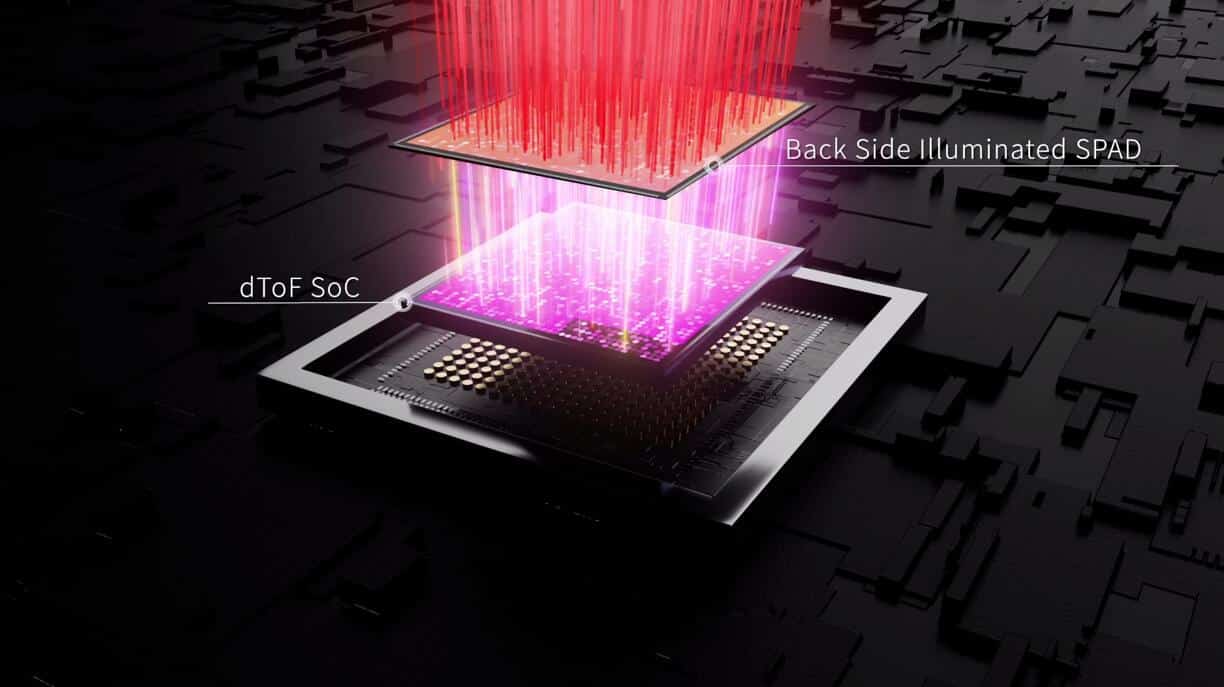

The LiDAR is built on RoboSense's in-house developed chip and a brand new technology platform, and the company's co-founder and CEO Qiu Chunchao said that this is another revolutionary product launched by RoboSense after the M1.

If M1 truly propelled the LiDAR industry into the era of mass production, then E1 will be the final piece of the puzzle for L4 in-vehicle LiDAR sensing, said Qiu.

The E1 has no moving parts inside, balancing LiDAR detection performance, cost and reliability while allowing for a reduced number of parts, the company said.

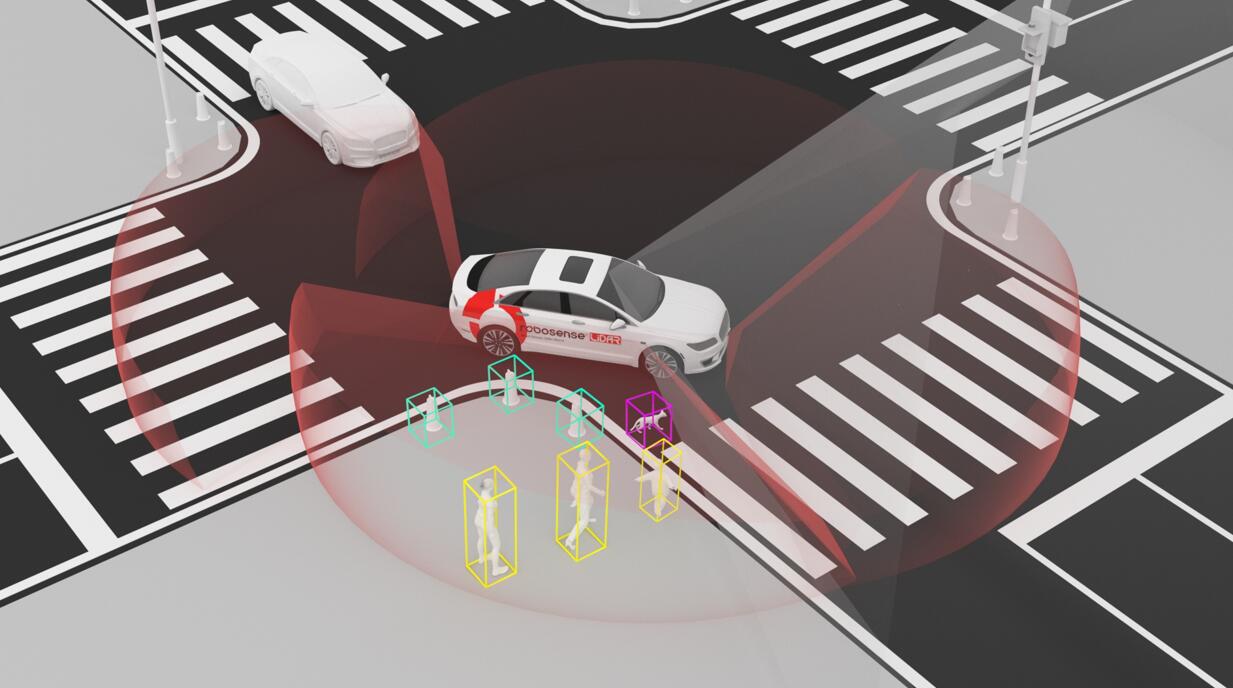

The LiDAR has a horizontal FOV of 120° and requires only two pieces to achieve a seamless 360° horizontal field of view stitching. Its vertical FOV is designed to be 90°, which allows the sensing range to balance ground blind areas with the lateral field of view, according to the company.

The E1 supports a refresh frame rate of more than 25Hz and can complete target acceleration sensing within 200 ms, enabling faster capture of target motion, the company said.

It can detect objects up to 120 meters away and can also detect high-speed vehicles to the side and behind, providing ample response time for autonomous driving systems, according to the company.

The move from mechanical to solid-state LiDAR products is a significant advancement for the industry, RoboSense said, adding that mass production of the E1 will begin in the second half of 2023.

Notably, before RoboSense announced the E1, its local counterpart, Hesai Technology, unveiled a similar product, the FT120, and said it had received orders for more than 1 million units, with deliveries set to begin in 2023.

The FT120 is a pure solid-state LiDAR in which the laser is transmitted and received entirely through the chip, Hesai said.

In addition to announcing the E1, RoboSense also unveiled at its Tech Day event a specialized lab for testing and analyzing LiDARs and their components.

The first phase of the lab, with an investment of RMB 50 million ($6.9 million), covers 2,800 m² and has nearly 50 professional engineers, including core team members with an average of more than 10 years of experience in the field.

Supported by more than 200 sets of test equipment, the lab has simulation testing capabilities for LiDAR full environment application scenarios and can conduct more than 120 tests, according to the company.

With the support of this lab, M1 has accumulated over 36,000 hours of high-temperature endurance testing, over 24,000 hours of high-temperature and high-humidity testing, over 21,000 hours of cyclic temperature shock testing, and over 40,000 hours of standalone device testing over the past two years.

Also at the Tech Day event, RoboSense announced Luxsense, a joint venture with electronics manufacturer and Apple supplier Luxshare, as a key component of the RoboSense smart manufacturing cluster.

The first phase of RoboSense's smart manufacturing cluster has an investment of over RMB 1 billion, with a plant area of over 55,000 square meters and nearly 20 automated production lines built, according to the company.