GAC Aion, a Chinese new energy vehicle manufacturer, launched a new battery technology called magazine batteries on March 10, becoming another car company that produces its own batteries after BYD.

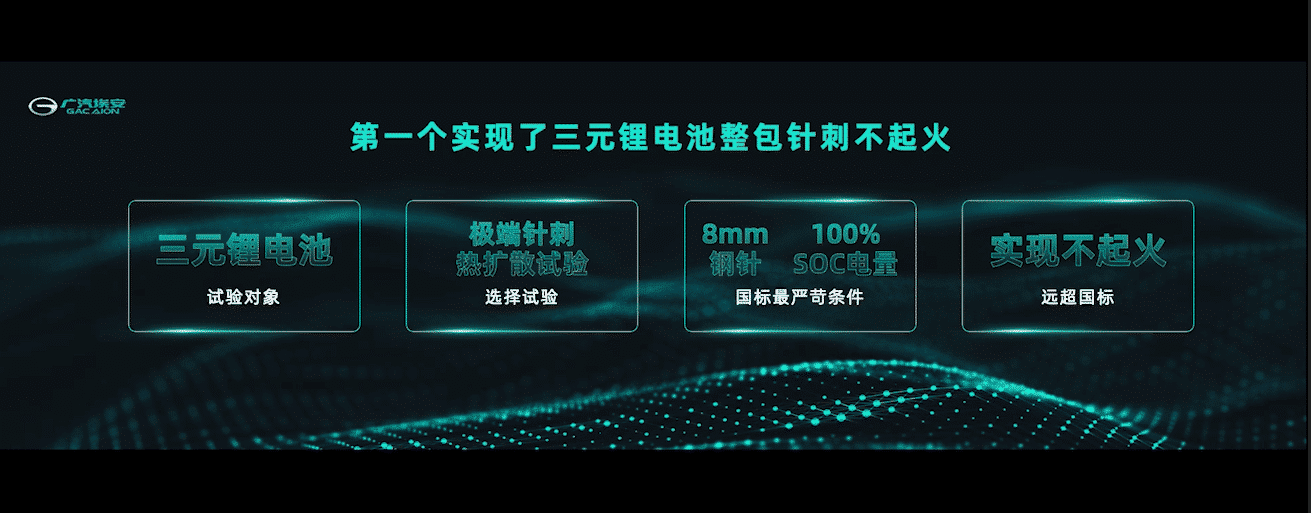

The technology, for the first time, achieved the whole pack of ternary lithium batteries to avoid fire during the nail penetration test, and also enables iron phosphate batteries not to smoke or catch fire in the nail penetration test, the company said.

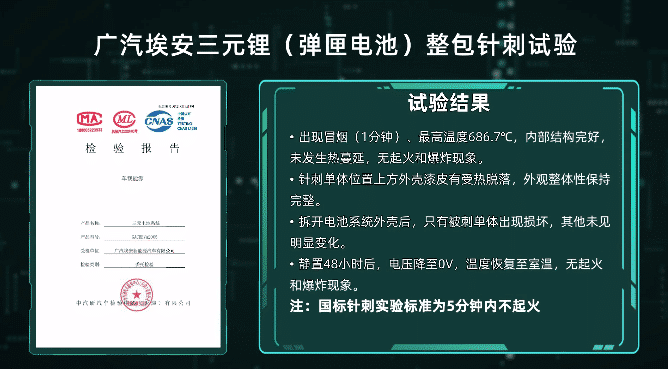

The test results show that the whole pack of GAC Aion's ternary lithium (magazine battery) only showed a brief smoke emission (1 minute) after the thermal accident signal was given for 5 minutes during the test, with no fire or explosion. After the battery rested for 48 hours, the voltage dropped to 0V and the temperature returned to room temperature.

After the test, only the pierced cell module had thermal runaway, and the situation did not spread to other cells. After opening the whole battery pack, the internal structure was found to be intact.

Compared with lithium iron phosphate batteries, ternary lithium batteries, despite their high energy density, have been criticized for their instability and have caught fire many times around the world, not to mention the possibility of passing the nail penetration test.

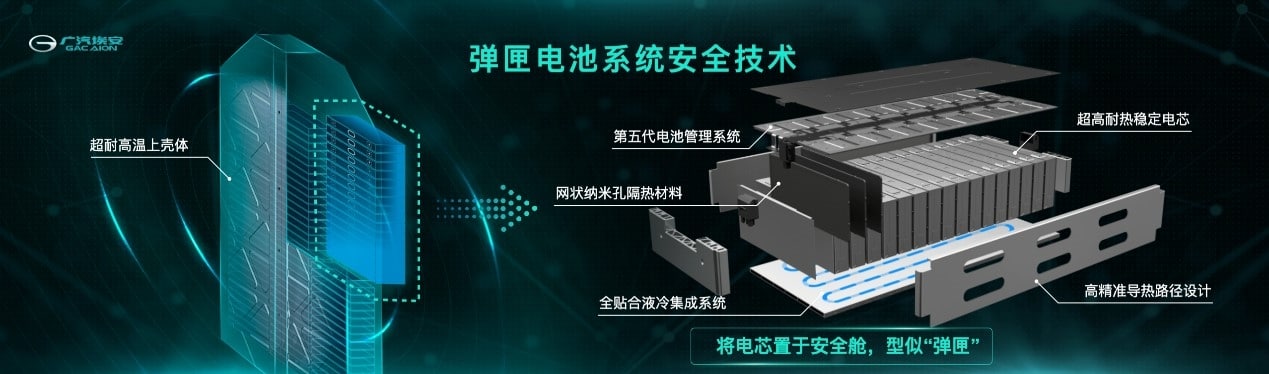

However, GAC Aion's magazine battery adopts a design similar to a safety chamber, which can effectively block the spread of thermal runaway cells, and automatically activate the quick-cooling cooling system to cool down the battery when abnormalities in cell voltage or temperature are detected.

The battery's energy density is 9.4% higher by volume, 5.7% higher by weight, and 10% lower by cost compared to similar ordinary battery packs, according to GAC Aion.

The cells of the magazine battery can withstand 1400°C high temperature by improving thermal stability through the application of the nanoscale coating and doping technology for the cathode material.

And two new additives have been added to the electrolyte, which can realize the functions of self-healing of SEI film and reducing the heat of thermal runaway reaction, respectively, and the diaphragm also uses an all-ear laminated sheet to accelerate heat dissipation by 10%.

The application of these key technologies has increased the heat resistance of the cells by 30% and the heat dissipation by 40%, according to GAC Aion.

The mag battery also does physical protection, i.e., through the mesh nanopore insulation material and high-temperature resistant upper shell, a super-insulated safety compartment is constructed, which ultimately realizes that the thermal runaway of the ternary lithium battery cell does not spread to adjacent cells.

In addition, the magazine battery is equipped with GAC Aion's fifth-generation battery management system, which uses the power not from the battery but from the power battery module.

The system can achieve 10 times per second, 24-hour data collection, real-time monitoring of the health status of the battery pack, and timely prevention of battery fire.

If abnormal conditions are found, the system can immediately start the battery cooling system for the battery to cool down.

The magazine battery system safety technology is to achieve high safety, long-range and low cost without sacrificing range and increasing cost, according to GAC Aion.

The magazine battery technology can be applied to the battery pack of both lithium iron phosphate and lithium ternary materials, and the power battery equipped with this technology will be installed in the whole series of AION models starting this year.

BYD conducts nail penetration tests on individual cells of the blade battery in 2020, plus the battery uses a more stable lithium iron phosphate battery, the battery cells do not catch fire as expected, according to eeo.com.cn, citing people familiar with the matter.

GAC Aion has become another car company that produces its own batteries after BYD, and in the future, the company will also supply its batteries to other companies.

"Our own batteries are our unique advantage and can be used in our high-end models, but it is worth considering whether to supply them to other companies." A senior executive of the company was quoted as saying in the above report, adding, "The purpose of developing our own battery is to control the core technology ourselves."

BAIC has already announced that it will release a graphene super fast-charging battery in September this year, which can be fully charged in eight minutes. In addition, GAC has also released a silicon negative battery and said the new battery can reach an NEDC range of 1,000km.

(Source: GAC Aion)