This insider perspective offers extensive previously undisclosed details, making it a rare and valuable read on Nio.

Nio Inc (NYSE: NIO, HKG: 9866) published a lengthy post on its social media accounts Thursday, reflecting on its decade-long chassis R&D journey as it reached the milestone of producing its 1-millionth vehicle.

The piece begins with Nio's origins in 2014, when it was still known as NextEV, recounting the challenges it faced in chassis development and how it overcame them.

From an insider's perspective, it provides those following Nio with a wealth of previously undisclosed details, making it a rare and valuable read.

Moreover, even viewed purely as a piece of storytelling, its writing quality ranks among the finest in China.

Nio founder, chairman, and CEO William Li shared the article on his personal Weibo account, noting that many scenes described remain vivid in his memory.

Given the article's valuable insights, we attempted a full Google Translate rendition with minor edits to preserve its core message.

Below is the full text:

Behind the 1 millionth mass-produced vehicle: Nio's decade-long battle to master chassis technology

On January 6, 2026, Nio's 1-millionth production vehicle rolled off the assembly line at its Xinqiao Advanced Manufacturing F2 Factory in Hefei.

Looking back over the past decade, cumulative R&D investments exceeding RMB 60 billion, over 10,000 patents, three generations of technological platform iterations, and unwavering strategic commitment to "technological advancement" have culminated in the delivery of this millionth vehicle.

Within the vast technological landscape underpinning these high-quality deliveries, one component epitomizes Nio's relentless pursuit of technological excellence and reflects the arduous evolution of China's automotive industry from follower to leader: the chassis.

This was once the last bastion of Europe's established automakers -- the most obscure jewel in the crown of automotive engineering.

The challenge of chassis development lies in its nature as a "multi-objective optimization problem" with no standard solution. It represents the deep integration of mechanical, hydraulic, electronic, and software systems -- a delicate balancing act between safety, comfort, and handling at the edge of physical limits.

For a long time, China's automotive industry remained largely "silent" in this domain. Whether domestic brands or joint ventures, the core hardware, control logic, and calibration models of chassis systems were almost entirely controlled by international Tier 1 giants.

For OEMs, the chassis was a tightly sealed "black box": its logic remained invisible, parameters couldn't be altered, experiences couldn't be iterated, and issues couldn't be swiftly resolved.

In 2014, Nio was founded. From the outset, it was a company determined to break the rules. But when it collided with the formidable wall of chassis technology, it discovered that rules exist precisely because breaking them demands enormous sacrifice.

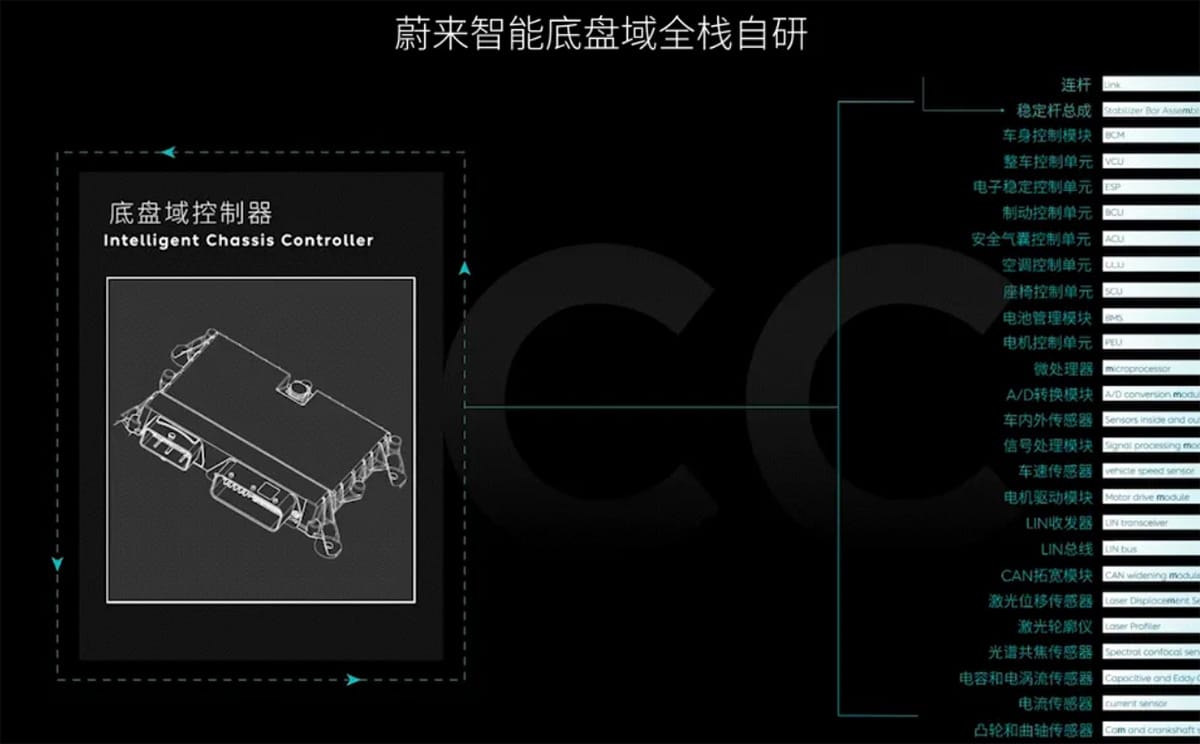

From initial uncertainty to independently developing the ICC (Intelligent Chassis Controller), then launching the ET9's SkyRide intelligent chassis, and finally rolling out 1 million production vehicles -- Nio's journey has been a long path from "passive adaptation" to "active definition."

This journey also encapsulates the evolution of China's automotive industry over the past decade: step by step, we've taken the wheel of our own destiny.

Let us revisit 2014, the starting point of this million-unit journey.

1. Schrödinger's air suspension and William Li's letter

The story traces back to 2014, when Nio was still known as "NextEV."

From the outset of Nio's first mass-produced vehicle (the founder's Edition ES8), the product definition was bold: to create a high-performance, premium smart electric SUV delivering a more sophisticated and luxurious experience.

Given this positioning, systematic chassis selection commenced, particularly in hardware where Nio spared no expense: adopting an all-aluminum structure while mandating air suspension and CDC dampers for dynamic performance.

In China's automotive market at the time, this represented a configuration frontier rarely approached by domestic brands.

As a domestic Chinese automaker, how could Nio achieve such high-specification selections within a diverse international supply chain? This posed a severe practical challenge for the then-unknown Nio and its chassis team.

Frank, Head of Vehicle Development Engineering at Nio, joined the company very early on. He recalls: "Top international suppliers didn't even know who 'NextEV' was. They ignored us completely. To secure top-tier air suspension and steering systems, our head of vehicle R&D and procurement director had to make multiple trips to Europe, visiting suppliers one by one to persuade them."

Ultimately, suppliers agreed to collaborate, but presented Nio with an entrenched industry rule -- the "off-the-shelf model."

"Suppliers were willing to cooperate, but only on the condition that we select from their existing mature product catalog, not pursue entirely new custom development."

Frank recalls: "The first-generation ES8 was indeed a frustrating endeavor. Even though we were willing to pay substantial development and tooling fees, we could only adapt existing products developed by suppliers."

Thus, despite the first-generation ES8 featuring the world's most advanced hardware at the time, incompatibilities arose from differing underlying control strategies across suppliers. For instance, the stiffness adjustment of the air suspension and the response control of the CDC lacked unified logic for deep coordination, resulting in perplexing inconsistencies in the vehicle's dynamic feedback.

After the founder Edition ES8 deliveries began, owners complained about the air suspension's unstable and unpredictable performance. One owner even wrote a nearly thousand-word essay on the Nio App titled "Schrödinger's Air Suspension," which sparked significant discussion -- garnering 2,756 comments alone.

For a company committed to leading in technology and user experience, this was unacceptable. Nio founder, chairman, and CEO William Li made his stance unequivocal in an internal meeting: "Resolve this issue at the fastest possible speed, whatever the cost."

Nio's chassis and product experience teams swiftly formed the "Schrödinger's Air Suspension" task force. However, they soon realized solving this problem would take more than a day.

This was the cost of the "black box": shock absorbers followed their own logic, air springs theirs, all sealed within the supplier's controller.

To adjust a single shock absorber's damping parameter, Nio engineers had to submit requests to the supplier, then wait for scheduling, validation, and feedback. Sometimes, a single subtle vibration filter required weeks of back-and-forth discussions.

It was a bleak period. In the era of smart electric vehicles, the chassis is the source of comfort for drivers and passengers. The team knew: if the chassis eroded user trust, the term "premium" would never become synonymous with Nio.

Late one night, William Li sat at his computer and drafted an email to the global CEO of a top-tier supplier.

Subsequently, both parties formed a joint task force. Nio urgently assembled all suspension technology experts from San Jose, Europe, and its Shanghai headquarters. The partner also reconvened senior engineers who flew to Shanghai. It took over two years to gradually restore the first-generation product's experience to industry-leading standards.

Yet for Nio's chassis team, what truly lingered from this ordeal wasn't the "conquest" itself, but an unsettling truth: as long as control remains out of their hands, even the finest hardware remains nothing more than a shackled shell.

2. After that Email: The seed for in-house ICC development was forced to sprout

When user feedback flooded the community and William Li sent that email, the chassis team engaged in profound self-reflection: What would Nio look like five years from now if we continued relying on black boxes? How could we talk about intelligence if chassis logic remained opaque? Where would user trust come from if we couldn't control the driving experience ourselves?

The answer pointed toward independently developing the Intelligent Chassis Controller (ICC), granting the "brain" absolute control over the "body."

Yet at the time, this decision had everyone holding their breath.

Fast forward to late 2019 and early 2020 -- Nio's darkest hour. With cash flow critically tight, investing heavily in an in-house ICC felt like walking a tightrope.

Dr. Xiao, Nio's Head of Vehicle Software Development, recalls that during the product decision meeting, the pros and cons across various dimensions were complex and intertwined. Yet after hearing all the reports, William Li brought the discussion back to the most fundamental "first principles." He posed two questions: "First, will the user experience be better? Second, can the iteration speed be faster?"

"If we followed the supplier's solution, fixing bugs would take half a year -- completely out of our control. User experience must come first." Guided by these two principles, William Li decided: in-house development.

Yet external challenges were even more immediate: international suppliers insisted on "bundled sales" -- want our air springs? Fine, but you must also buy the controllers and algorithms. If you only want the mechanical hardware, I won't sell it.

Nio needed to develop its own ICC, but international suppliers refused to provide mechanical hardware separately -- especially the critical air springs. Consequently, Nio decided to seek domestic suppliers capable of mass-producing air springs independently.

After surveying every domestic company with air spring experience, the Nio team found none with OEM experience. However, one company had aftermarket repair experience for Mercedes-Benz, BMW, and Audi.

Faced with a supplier needing to start from scratch in air springs, would they dare to use it? Could it work? Was this even feasible? Nio's confidence stemmed from the "frustrating" lessons learned during the first-generation ES8's development.

During the ES8's R&D, European suppliers' validation cycles (typically 6-10 months just for mold development) were excessively long.

Nio's chassis team pioneered validation methods tailored to Chinese driving conditions, proactively breaking conventions: devising solutions and testing during the day, immediately revising plans with partners overnight if results were unsatisfactory, and retesting first thing the next morning.

Ultimately, within an extremely tight timeframe, they ensured the high-quality integration of this critical air spring component.

This grueling two-year-plus endurance test forged a team of engineers proficient in chassis design and validation. "Even though our partner had nothing at the time, we had a team of engineers forged through the ES8 generation."

The final decision hinged not only on technical capability but also on the partner's commitment to sustained investment. Before finalizing the deal, Nio Executive Vice president Shen Feng specifically spoke with the founder of this domestic air spring supplier: "Are you willing to pioneer this field with Nio? Do you have the resolve to invest real capital into building a factory?"

Their answer was unequivocal: yes. Consequently, Nio's chassis team undertook an uncommon move for an automaker: helping their partner "start a business." "We even assisted in interviewing their first batch of engineers," Frank noted.

Having resolved constraints on critical chassis hardware like air springs, Nio next tackled the physical carrier for ICC's "brain" -- the domain controller hardware.

While Nio mastered core control algorithms (software), manufacturing controllers required specialized production lines and processes (like PCB assembly).

Continuing to outsource to foreign manufacturers still posed "black box" risks, so Nio also partnered with a domestic controller supplier.

"This isn't just a buyer-supplier procurement relationship -- it's a 'white-box model,'" explained Dr. Xiao. "We operate on complete mutual trust with shared technical IP. It's no longer about handing a requirements document to a supplier and waiting for delivery; instead, we've fused the two teams together."

This formed Nio ICC's "joint task force": the local partner tackled the manufacturing processes for mechanical hardware (air springs) and electronic hardware (controllers) on both sides, while Nio contributed the most critical "soul" -- fully in-house developed control software and system integration.

The deep collaboration quickly paid off. "Previously, the fundamental theories for electronic suspension control were based on classic papers from the 1970s and 1980s in the US and Germany. These theories evolved very slowly, but China's complex road conditions forced us to rapidly iterate our algorithms," said Dr. Xiao. Through this joint development, partners' capabilities rapidly improved, while Nio successfully broke the monopoly of international suppliers.

In 2021, the ET7 equipped with ICC was launched. This marked China's first mass-produced intelligent chassis domain controller developed entirely in-house.

From an engineering perspective, ICC achieved two key milestones.

First, it transformed suppliers' "black boxes" into "white boxes." Nio engineers could finally bypass suppliers to directly modify parameters and deploy algorithms at the domain controller level. The chassis now possesses OTA evolution capabilities, much like a smartphone.

Second, it dismantled "isolated islands." The ICC integrated control functions for redundant parking, air suspension, shock absorbers, and more. It transcended being a simple aggregation of subsystems, instead unifying them into an organic whole.

Today, in-house development of chassis domain controllers is an industry trend. But looking back, Frank still remembers the conversation he had with Zhou Xin, Nio's Executive Vice president, after that fateful product decision meeting.

Zhou Xin asked him, "Why did you dare to take this on?" Frank replied, "The chassis has three major challenges: suspension, steering, and braking. We'll tackle them all eventually. If Nio doesn't take the first step, no Chinese automaker might ever become the pioneer."

It was this resolve -- "to eventually move the mountains" -- that propelled Nio beyond the "black box era" into the "era of in-house developed systems" through the ICC leap.

Engineers could finally declare: "If a user reports poor experience on a certain road segment today, we can quickly push an updated logic version to them."

This sense of control is addictive. But for a team of engineers hungry to reach the summit, it wasn't enough. When the ET9 project launched in 2022, they set their sights on even steeper peaks.

3. The "Mule Car" that nearly died, and that winter in Coventry

With a brain in place, Nio began craving stronger limbs. In 2022, as ET9 development commenced, the Nio team grappled with a question:

What breakthroughs should the future flagship chassis achieve? On the table lay several seemingly irreconcilable contradictions: executive-class long wheelbase vs. cornering agility, posture stability vs. diverse driving conditions, effortless handling vs. precise steering, plush comfort vs. rapid dynamic response.

Engineers compiled all these "impossible-sounding" goals onto a single sheet of paper -- dubbed the "Dare to Dream List."

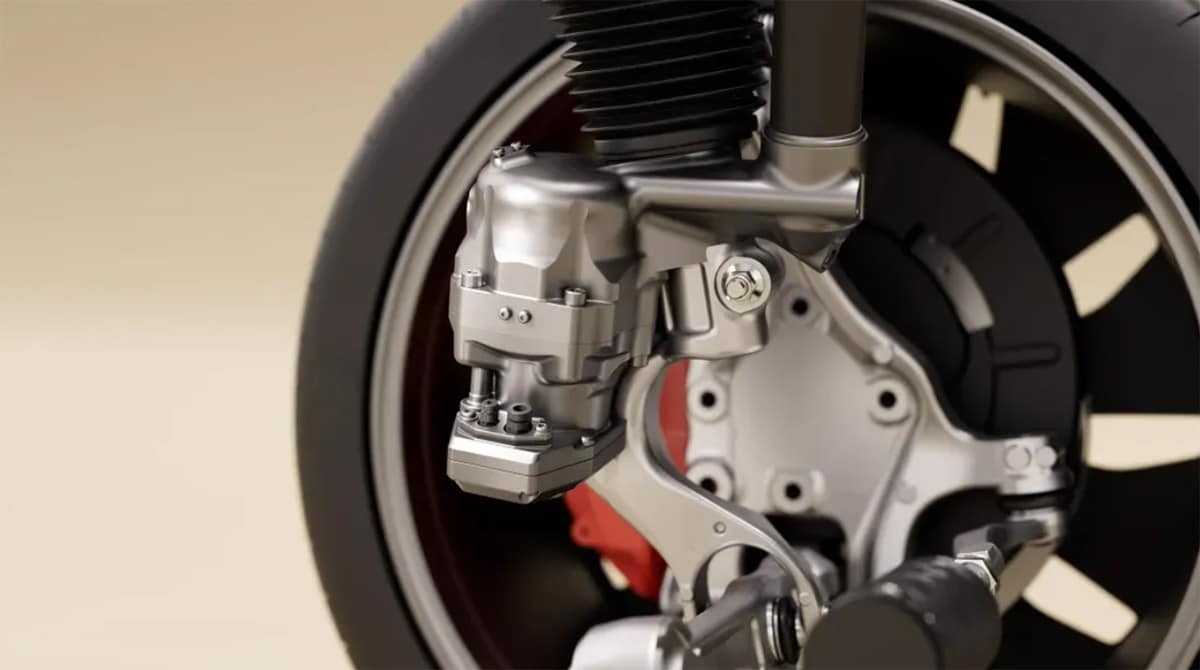

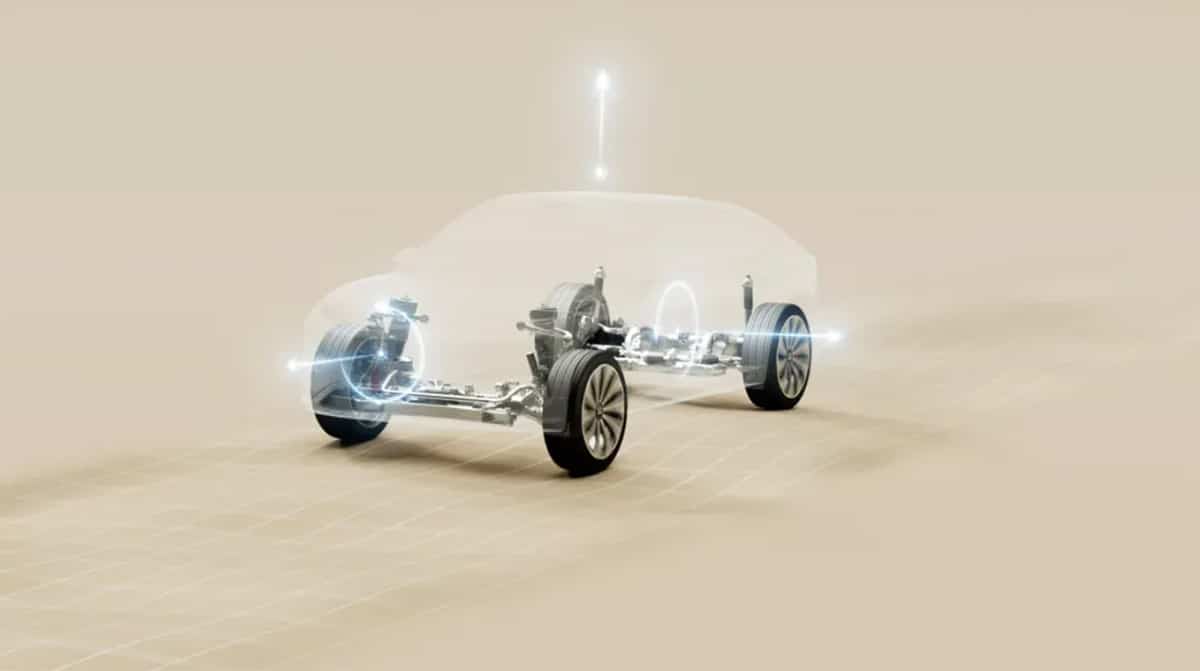

Topping that list were three technologies widely regarded as the industry's "Mount Everest": Full Active Suspension (FAS), Steering by Wire (SBW), and the VMC Chassis Intelligent Computing Platform.

Any single one of these technologies could easily consume hundreds of engineers and years of development, driving an automaker to anxiously shuttle between test tracks and conference rooms. Nio's challenge? To make them all work together. Not just function in tandem, but understand each other, collaborate, and even "cover for one another."

The turning point began with an adventure across the ocean.

During a 2022 business trip to Europe, William Li discovered the startup ClearMotion at a technology exhibition. The demo of their Full Actuated Hydraulic Suspension (FAS) was breathtaking: leveraging the high-frequency responsiveness of hydraulic pumps to actively counteract the laws of physics, eliminating every single bump in the road.

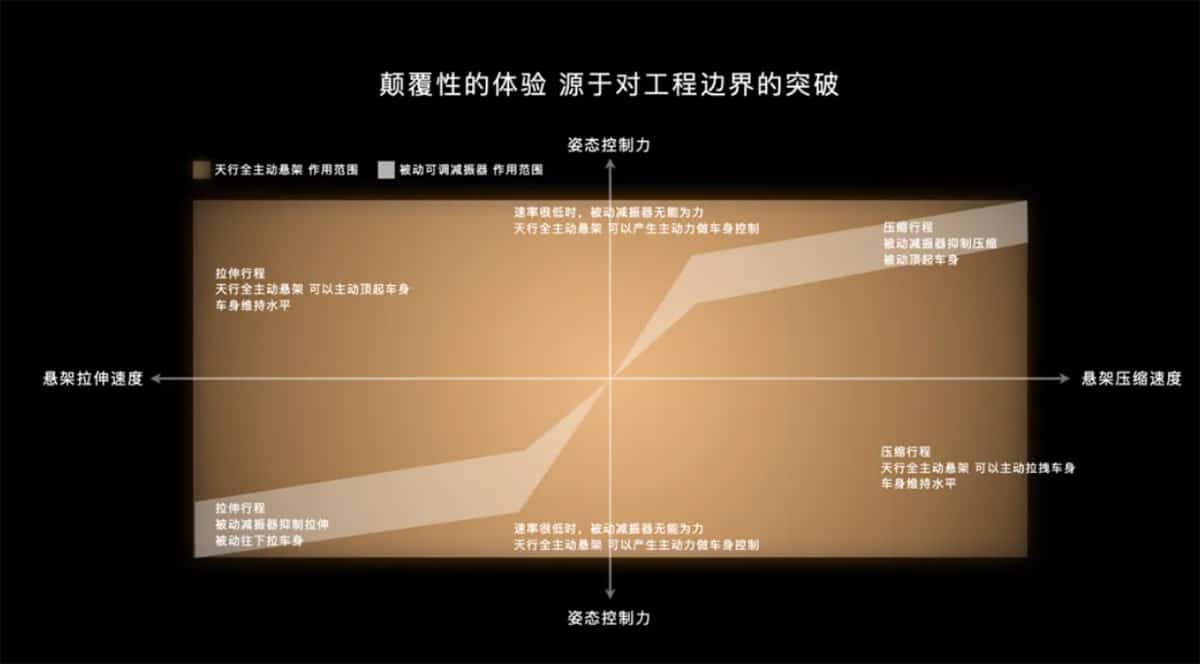

As Joe (ClearMotion's senior technical expert) put it, if traditional suspension is like passive noise-canceling earmuffs, Full Actuated Hydraulic Suspension is like "advanced active noise-canceling headphones": Body bounce and roll have specific frequencies. FAS generates a counterforce that 'cancels out' vibrations before they reach the rear seats. This achieves ultimate body stability, leaving occupants undisturbed."

This perfectly aligned with Nio's vision for its flagship ET9 model. Yet the collaboration's early stages proved far more challenging than anticipated.

Though ClearMotion had MIT academic credentials, they lacked mass production experience at the time.

Figo, Nio's suspension development lead, recalls the initial encounter with ClearMotion, acknowledging the immense challenge: "Their technology demo was breathtaking, but transforming it into a vehicle-grade mass-production product required a long journey."

Faced with a disruptive technology never validated in production vehicles, how could engineering certainty be assured? This became the focal point of Nio's internal discussions.

Out of rigorous consideration for the flagship model's delivery timeline, the team devised a meticulous Plan B: if the FAS solution encountered insurmountable obstacles, they would activate the proven "CDC + dual-chamber air spring" solution as a backup.

To validate whether this system truly works, Nio modified an ES8 into an engineering verification vehicle. Internally, engineers dubbed it the "Donkey Car," specifically designed to test the brand-new subsystem.

The vehicle was first shipped to the UK. On ClearMotion's test track in Coventry, it performed like a gentleman.

But when it was shipped back to China and first driven on the complex, patchwork roads filled with seams and repairs, this gentleman instantly "broke down."

"The impact was immense, completely unacceptable," Figo recalled. "The vibrations were transmitted without any filtering -- it felt worse than a regular car."

The stark psychological contrast plunged the project team into crisis. At the review meeting, pessimism hung heavy. "Everyone felt this wasn't roadworthy," Figo recalls. "Some even suggested reporting to Bin to scrap the project."

For a conventional automaker, the story would have ended there -- opting for a proven solution with minimal risk, and no one would blame them.

But Nio refused to give up. Because Figo and his team understood clearly that their mission wasn't just about lap times on a racetrack, but addressing pain points unique to Chinese road conditions.

Take the "overpasses" on Chinese highways. When you hit 120 km/h on the ramp, the car gets lifted up, then slams back down. That feeling of weightlessness is the enemy of luxury. Only a lightning-fast system like FAS could smoothly keep the body planted.

In October 2022, two engineers from Nio's Vehicle Dynamics and Vehicle Motion Control teams flew to Coventry, UK, under immense pressure.

During that cold, wet winter, they spent an entire month working alongside ClearMotion's team.

"We didn't just go for testing -- we brought Nio's peripheral components and control logic with us," they recalled.

Ultimately, the Nio team completely overhauled the hydraulic matching logic of the entire system. They meticulously tuned that suspension -- originally "pampered" for European road conditions -- to adapt to China's challenging terrain.

A month later, this 'surgery'-enhanced "Donkey Car" was shipped back to China.

This time, William Li personally test-drove it. After stepping out, the project was given the green light.

4. "Stop, don't change it anymore -- it's already good enough."

"Donkey Car" survived, but when the ET9 entered the prototype phase, the real technical black hole was just beginning to emerge.

The testing team discovered a ghostly glitch on the test track: when passing over certain specific, extremely short bumpy sections, the fully active suspension would unexpectedly shut down. Yet at ClearMotion's UK facility, the issue never resurfaced.

To capture this "ghost," Nio engineers camped out day and night at the test site. Finally, they caught the moment -- when the vehicle traversed a specific joint, the suspension system triggered a spike current lasting a mere 5 microseconds.

Five microseconds -- merely a fraction of a blink. Yet the FAS demands extreme performance: processing and responding within a millisecond, lifting a two-ton vehicle body 50mm in 0.4 seconds -- 60 times faster than conventional air springs.

This explosive force means the power system must withstand intense forward and reverse current surges on a microsecond timescale. Any insufficient power supply or misjudged protection logic would instantly paralyze this precision machinery.

This phenomenon arises because conventional chassis development typically focuses on millisecond-level response characteristics. Yet when this top-tier fully active suspension encounters China's complex road conditions, microsecond-level responsiveness becomes essential.

Nio identified this challenge because the ET9 employs full-vehicle eFuses. These electronic components enable node-level precision control, proving more sensitive -- yet also more unforgiving -- than traditional physical fuses.

Existing 48V power system architectures cannot address this issue. Even the half-century-old 12V system relies more on industry experience than forward-engineered solutions.

To address this, Nio swiftly formed a cross-departmental task force dedicated to the 48V power system. They designed their own test rigs, conducted 156 full-road-condition simulations, and extracted 14,535 power-current spectrum data points ranging from 5 microseconds to 100 milliseconds. They employed the most straightforward yet robust approach: exhaustive testing.

It was precisely through this tedious data collection that Nio established forward-design specifications for the 48V power system from scratch.

While tackling the "5-microsecond" challenge, engineers faced an even more fundamental concern: FAS is a "power-hungry beast that devours range."

While fully active suspension is powerful, it requires constant energy consumption to counteract the laws of physics. At full power output, instantaneous energy consumption can reach several kilowatts.

"For electric vehicles, sacrificing dozens of kilometers of range for comfort is something users absolutely cannot accept," said Figo.

To tame this "power-hungry beast," Nio's engineers devised an exceptionally clever "division of labor strategy."

From the initial architecture design phase, the team rejected relying solely on FAS to support the body, instead insisting on a combined "air spring + FAS" approach.

"We have the air spring handle the 'heavy lifting' -- maintaining body height over extended periods, since trapping air in the bladder consumes no power. FAS only handles the 'quick work' -- managing instantaneous bump adjustments."

More notably, this system was engineered as an "energy micro-circulation" system.

"FAS not only consumes power, it also generates it," Figo explained. When wheels compress under road impacts, FAS motors can instantly recover up to 5kW of energy in reverse, akin to kinetic energy recovery. The system prioritizes "temporary storage" of this recovered energy for the next suspension extension.

Through this millisecond-level "meticulous management," Nio successfully kept the energy consumption of this flagship system at an extremely low level. They even added 300 hours of dedicated endurance testing for "entertainment" scenarios (like the body-dancing feature) to ensure absolute reliability.

This relentless pursuit of extreme detail left the ClearMotion team both frustrated and in awe. Over two years of collaboration, Joe's deepest impression of Nio engineers was their "greed" and "speed."

"The hardest part of this project wasn't solving technical challenges -- it was telling Nio engineers: Stop. Don't tweak it anymore. It's already good enough," Joe half-jokingly complained.

From software control strategies to hardware specifications, Nio consistently demanded standards slightly higher than industry norms. Yet it was precisely these countless incremental improvements that ultimately shaped the ET9 chassis's refined quality.

ClearMotion ultimately achieved an unprecedented level of synergy with Nio. Joe Belter concluded the interview by stating: "Nio is incredibly bold -- the first company daring to bring this technology to market. The Nio ET9 is the true pioneer of this technology."

At Nio Day 2024, when the ET9 glided effortlessly over speed bumps while supporting a five-tier champagne tower, and when the vehicle instantly lifted its body like a rocket launch during simulated rear-end collisions, users witnessed a breathtaking "magic trick."

But for Figo and the Nio chassis team, these were merely "side effects" derived from developing the core functionality of the fully active hydraulic suspension.

"The champagne tower test fundamentally tests 'Leveling' -- ensuring the car remains perfectly level when crossing a cross-axle. The snow-shaking test tests 'High-Frequency Response' -- filtering out those nerve-wracking, fine vibrations from the road surface."

This embodies Nio's chassis development philosophy: pursuing "performance that exceeds expectations and comprehensive peace of mind," truly addressing the most common pain points on Chinese roads.

5. That Silicon Valley turn and the all-In commitment

If active suspension represents the pinnacle of comfort, then SBW (Silicon-Based Wheel) redefines the driving experience.

Some might view Nio's adoption of SBW in the ET9 as radical. In reality, this architecture was already under internal discussion during the 2019 planning phase for the second-generation platform. The goal was to create a premium smart electric SUV, with a clear foresight that SBW was an essential path toward future autonomous driving.

That year was dubbed Nio's "darkest hour" by outsiders. Yet away from the spotlight, Nio dispatched a seven-to-eight-person executive team on a secret mission to South Korea and Silicon Valley. Their objective: to scout next-generation chassis technology.

At Nio's North American headquarters in San Jose, a peculiar vehicle sat parked. It was a modified ES8 mule car -- the mechanical column connecting the steering wheel to the steering gear had been removed, replaced by a bundle of wires.

William Li and Nio's Head of Product Experience, Li Tianshu, made a special trip to test it. William Li sat in the driver's seat and instinctively turned the wheel.

Being a proof-of-concept prototype with no physical limits, the steering wheel whirled past its limit like an uncontrolled roulette wheel. The wheels instantly locked, causing the massive SUV to perform a comical 180-degree spin.

Everyone present laughed. But behind the laughter, William Li's eyes gleamed.

"If the steering wheel and wheels are completely decoupled, it could deliver an entirely new driving experience," William Li told the engineers present. "The front cabin space could be freed up. During assisted driving, the steering wheel could retract. Wheel turning angles would no longer be constrained by the number of steering wheel turns..."

That marked SBW technology's earliest "moment of glory" within Nio. Yet reality soon poured cold water on the vision. As a funding crisis erupted in late 2019, countless cash-burning forward-looking projects were halted to ensure survival.

SBW, this "cash-guzzling beast" that never made it past the project proposal stage, was shelved in the archives.

By 2022, Nio had decided to launch its flagship executive sedan, the ET9. The filing cabinet was reopened, and the "Dare to Dream List" was laid out on the table.

At this juncture, Nio faced a monumental decision. Traditional OEMs developing SBW typically maintain a fallback: retaining a mechanical steering column as redundant backup -- using electric steering normally but switching to mechanical in emergencies. Alternatively, they develop dual steering systems -- one conventional, one electric -- so if SBW fails, the conventional system can launch.

But Nio's decision was: All-in.

"On the ET9, we're completely eliminating the mechanical steering column. No mechanical backup. No dual configurations." William Li and the R&D lead finalized the decision at the meeting.

At the time, this decision seemed almost insane. The steering system is a matter of life and death; failure means major accidents. Removing the mechanical link meant staking the vehicle's entire safety on electronic signals and software algorithms.

Behind this all-in approach lay an extreme focus on safety and an uncompromising pursuit of overall vehicle performance.

Dr. Xiao, Nio's Head of Vehicle Software Development, defined it as a leap in understanding: "Previously, when developing SBW (Steering By Wire), everyone focused solely on the safety of the 'SBW system' itself. But what we're doing now is 'generalized safety.' The safety of SBW isn't just provided by the system itself; it must be supported by all levels of safety backups across the entire vehicle. Even if the steering system fails, this vehicle still has ways to remain controllable."

This philosophy later became a key factor in persuading regulatory authorities during the mass production of the ET9.

So how does one ensure vehicle controllability under any failure scenario? Faced with this ultimate challenge, Nio didn't develop in isolation but looked to the skies for inspiration.

"As early as 1974, the F-16 fighter jet pursued extreme maneuverability by becoming the first combat aircraft to adopt full-authority digital fly-by-wire control without mechanical backups, introducing multiple redundant systems for this purpose. By 1987, the Airbus A320 brought this technology into the civil aviation sector," explained Nio steering system development expert Miao Gong, citing half a century of aviation industry evolution as evidence.

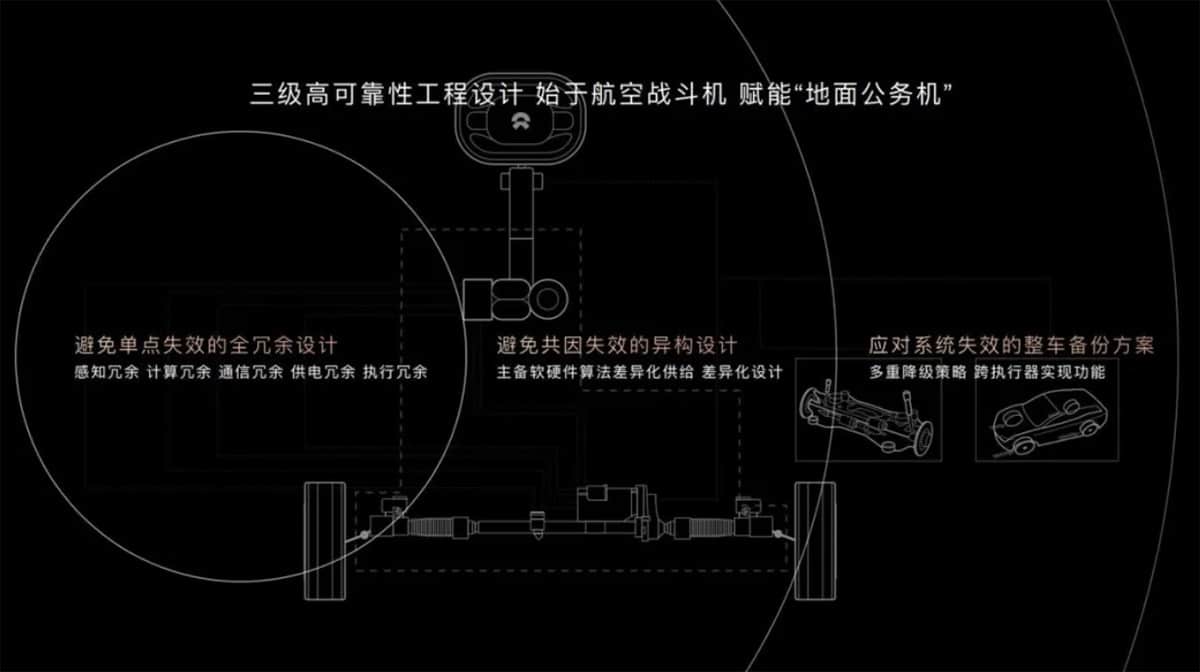

On the ET9, this "aircraft-grade triple-redundant reliability engineering" manifests as a watertight defense system:

The first tier is "omnidirectional redundancy." This goes beyond simple dual motors to encompass saturation backup from the ground up: computational redundancy (dual MCUs + independent control unit chips), communication redundancy (dual CAN bus lines), power supply redundancy (dual DC-DC converters + dual battery banks), execution redundancy (six-phase motors), and perception redundancy (multiple sensor channels).

The entire system functions like two independent brains and nervous systems. Should any link fail, the other can take over within milliseconds.

The second layer is "heterogeneous design." "Just as a pilot and co-pilot on an airplane cannot eat the same meal," to prevent a single bug from crippling both systems simultaneously, the ET9's primary and backup systems utilize hardware from different suppliers and run fundamentally distinct software. The primary system prioritizes full-featured performance, while the backup system focuses on high-reliability fallback. This fundamentally eliminates "common-cause failure."

The third level is "whole-vehicle redundancy." After rigorous testing, the ET9's SBW system has a steering failure probability of just 4.5 FIT. In engineering terms, this means only 4.5 failures per billion hours of operation. This figure is 2.2 times more reliable than traditional mechanically connected EPS systems.

Powered by Nio's in-house developed VMC (Vehicle Motion Control) platform, the ET9 integrates the entire vehicle's critical systems. Even if that 4.5-in-1-billion probability materializes -- resulting in complete SBW failure.

The ET9 can still engage rear-wheel steering and brake control (differential steering) to provide steering force and bring the vehicle to a safe stop.

"We transformed previously independent systems -- brakes, suspension, and electric drive -- into backup components for the steering system," confirmed Dr. Xiao. "The ET9's seven-layer safety redundancy, often emphasized by Bin, is no exaggeration in engineering logic."

Beneath these grand architectures, the true contest lies in minute details.

During development, the team faced a difficult decision: To address the extreme scenario of simultaneous failure of both upper steering channels, should an angle sensor independent of SBW be introduced?

This would mean additional costs and development complexity. Two opposing viewpoints emerged within the team: "The probability of dual-channel failure is already extremely low -- is it necessary to add another layer?" versus "Even if the probability is minuscule, we must ensure absolute safety."

These two perspectives clashed intensely yet intertwined. Ultimately, the team reached a consensus: When it comes to safety, there are no cost calculations -- only a binary choice of "do" or "don't." We chose to do. Thus, the independent angle sensor was installed, and dual batteries were introduced. Even if the entire SBW system fails completely, the vehicle can still achieve a safe stop using braking and rear-wheel steering.

When safety ceases to be a constraint, the full potential of technology is unleashed.

By eliminating mechanical connections, the ET9's front compartment gained space, allowing for more comprehensive collision safety design. The absence of mechanically transmitted vibrations resulted in a qualitative leap in NVH performance.

Confronting technology head-on, Nio chose to pursue the ultimate experience through the most challenging "full redundancy" approach -- rather than merely patching up the mechanical pillars of the past. This is Nio's choice.

6. The unending battle

In truth, Europe's automotive industry began exploring SBW as early as two decades ago. Yet during the long golden age of internal combustion engines, this technological seed never took root under Europe's conservative decision-making systems and complex legacy burdens.

By the 2020s, as the wave of advanced smart driving assistance swept in, the mechanical steering column -- the very barrier between drivers and autonomous algorithms -- emerged as the greatest obstacle.

Nio and ZF have a long-standing partnership. On this critical point, both companies reached remarkable consensus, immediately aligning to launch a joint development initiative designated "CAT ZF" (highest priority) internally at ZF.

This was an engineering campaign without precedent. Unlike the traditional "seller's market" where giants set standards and automakers simply adopted them, the ET9 project broke down barriers. Driven by Nio's forward-thinking product definition and industry-defying demands, both parties embarked on a deeply integrated, full-stack collaborative development.

The collaboration proved far more challenging than anticipated. Both Nio and ZF underestimated the behavioral variations of an executive-class vehicle like the ET9 under complex road conditions. With mechanical linkages eliminated by drive-by-wire technology, every aspect -- feedback, damping, self-centering torque -- became entirely software-controlled.

As scenarios grew more complex, software complexity expanded not linearly but exponentially.

To address this, Nio and ZF adopted a "non-stop" R&D model: ZF dedicated over 200 engineers to this project -- more than ten times the usual allocation.

Nio engineers ran tests at the Anting test track in Shanghai until late at night, transmitting data to the German team just starting their shift. The German team conducted simulations and sent results back to Shanghai early the next morning for real-vehicle validation. "You clock in, I clock out; you sleep, I charge ahead."

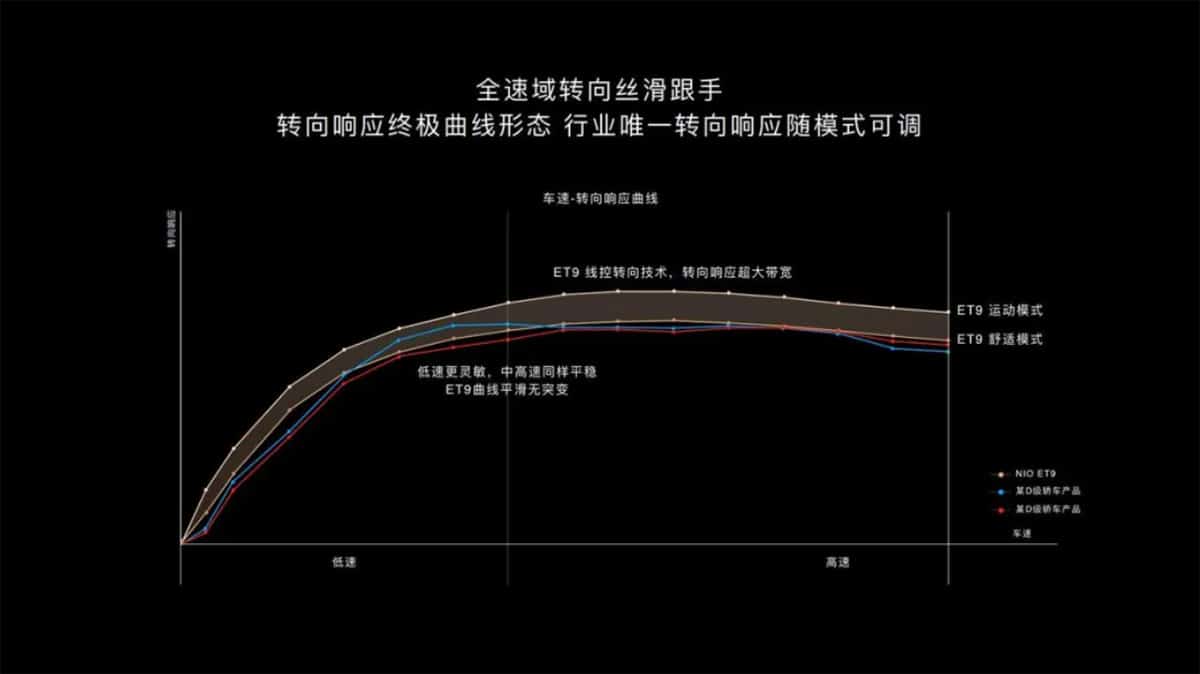

Throughout this process, both parties resolved numerous physical challenges, such as the "driver moves fast, car moves slow" issue.

A key advantage of SBW is its "variable steering ratio" -- at low speeds during parking maneuvers, a small steering wheel angle produces a large wheel turn (the ET9 can even achieve a full wheel turn with a single full steering wheel rotation).

But this introduced a physical challenge: the driver's hand moves extremely fast, while the motor needs time to turn the heavy wheels through a large angle.

"In early demo vehicles, your hand would turn the wheel, but the wheels wouldn't follow through. That latency was around several hundred milliseconds, but to the driver, it felt like 'the car doesn't respond to the steering' -- which was unacceptable."

To eliminate this fraction-of-a-second delay, the R&D team redesigned a high-power motor specifically for ET9, boosting its output by 50%. Simultaneously, engineers from both sides relentlessly refined the control algorithms, squeezing signal transmission latency down to the microsecond level.

Ultimately, the ET9 achieved unprecedented "elegance." In low-speed scenarios, its steering wheel features a single-side rotation angle of 240°, requiring just 0.66 full turns for a complete lock-to-lock -- eliminating the need for hand-crossing maneuvers and delivering effortless, graceful control.

One media tester noticed a touching detail during the experience: previously, when driving an executive sedan in a suit, sharp turns would tug at cuffs and elbows. With the ET9, one hand effortlessly completes the maneuver -- "not only does the driver feel elegant, but even the suit looks more refined."

This elegance reaches its zenith during parking maneuvers. When using automated parking, SBW requires only a 10° steering wheel adjustment to indicate direction, eliminating the frantic, dizzying spins of traditional steering wheels.

According to Nio's backend calculations, this SBW + rear-wheel steering combination can save users over 10,000 steering wheel turns annually.

From agile low-speed handling to the composed stability of a 14:1 steering ratio at high speeds, Nio's engineering team flexibly adjusted across an immense bandwidth to achieve optimal steering response in every scenario.

This cross-time-zone battle ultimately yielded SBW's ultimate safety and performance: it functions as both an ultra-responsive digital system capable of millisecond command execution and a gentle, considerate filter that silently absorbs excess vibrations from rough roads and deep manhole covers, leaving only pure road feel.

"We wrote millions of lines of code and conducted validation over thousands of days and nights, covering millions of kilometers -- all for one purpose," reflected Engineer Miao. "It's so that the moment users grip the steering wheel, they feel none of this code exists. Only safety and elegance remain -- no interference."

From "off-the-shelf" to "joint development," the ET9 has witnessed the reshaping of supply chain relationships. Today, the software logic and implementation expertise honed in China are being adopted by partners as cutting-edge models, reverse-exported to their global markets.

Hardware challenges proved equally formidable during ET9's SBW development.

To natively support advanced smart driving assistance, the ET9 required a long-travel electrically adjustable steering column to free up space for the driver. This meant the column's extension range had to reach 153 millimeters -- 2.5 times that of a traditional mechanical steering column.

Searching the global supply chain revealed no existing technology. Nio decided to design the long-travel steering column themselves, then jointly develop it with domestic partner Jilin Shibao.

Developing a long-travel electric steering column wasn't the challenge -- the real hurdle was creating one that met stringent NVH, stiffness, and durability requirements within limited space.

It was a painful "trial and error" process. The longer the column, the weaker its stiffness; the faster the adjustment, the louder the noise.

When the first prototypes were installed in vehicles, extension/retraction noise peaked at 50 decibels -- akin to a cheap electric drill. For the ET9, aspiring to be an "executive flagship," this was disastrous.

During the most challenging phase, engineers took up residence at Nio's Shanghai R&D center. For three months, they reviewed blueprints daily, debated structural solutions, validated designs on test benches, and replicated issues in vehicles. Like watchmakers, they meticulously refined each component.

To tackle the noise regulation challenge, Nio's lead engineer dedicated six consecutive months to independently designing verification protocols and testing dozens of solutions.

Finally, late one night, as the latest test data flashed "40 decibels," the lab fell silent.

No one cheered; everyone simply nodded in unspoken agreement. That silence embodied the unique camaraderie among engineers -- and marked the moment when Chinese manufacturing transcended 'functional' to achieve "excellence."

Ultimately, Nio achieved the world's first mass-production-level integration and validation of an advanced SBW system, elevating Shibao into a higher-dimensional R&D ecosystem. The know-how accumulated during this process will now flow into all subsequent projects, becoming the supplier's true capability.

There are also some industry-accepted "rules" -- Nio suppliers automatically enjoy "exempt from inspection" status, a notion widely circulated on social platforms. Nio's supply chain lead smiles wryly, "Actually, it's quite the opposite. When you're willing to go deeper than others, the supply chain opens deeper doors for you. We're using our own standards to grow alongside the supply chain."

7. From disruptor to benchmark setter

The technology was developed, but mass production faced one final hurdle -- the most challenging one: regulations. SBW is among the most sensitive systems in the automotive industry, demanding the highest level of rigor for every safety interpretation, test report, and risk matrix.

In fact, Nio nearly found itself barred from mass production due to regulatory issues.

Fast forward to July-August 2023, when industry regulations were tightening. Facing uncertain market access risks, Nio internally experienced a period of intense wavering.

"Can we create a backup plan?" someone proposed. "Reinstall the mechanical steering column in the ET9. If the steer-by-wire system doesn't get approved, at least we can sell the cars on schedule."

The regulatory certification team presented this idea to engineering, only to receive a cold response: "There's no turning back."

The ET9 project had already advanced into critical development stages. The front compartment layout was locked in. Forcing a mechanical column into the design would not only be impossible due to space constraints but would also require completely overhauling the chassis architecture and crash safety design. The cost would be astronomical, and the ET9's launch window would be irretrievably missed.

"That's when we realized this was destined to be a classic, bruising battle," " recalled Kevin, Nio's regulatory affairs lead.

The real challenge lay in the fact that while the 2021 national standards had removed the ban on "installing full-power steering (SBW) mechanisms," this version lacked an evaluation system and testing methods for SBW systems. Consequently, SBW system approval still faced the awkward predicament of having no standards to follow.

"This was previously an almost unsolvable vicious cycle," explained Dr. Xiao. "Regulators, prioritizing safety, were concerned about the lack of empirical data; yet the industry's dilemma was that without allowing vehicles to enter mass production and hit the roads, such data could never be generated."

Nio could only navigate an extremely narrow path -- the new technology review process. This path existed almost purely in theory, with few automakers ever successfully navigating it. It required convincing a panel of the most rigorous experts to believe in a technology that defied conventional wisdom.

After relentless effort, in April 2024, China's Ministry of Industry and Information Technology convened two technical review committees -- comprising departmental officials, testing institutions, and industry experts -- to evaluate the SBW technology in the ET9.

During the five-month review period, Nio's regulatory certification team organized a joint "preparation team" comprising multiple departments including chassis, vehicle control, and functional safety, becoming regular visitors to the China Automotive Technology & Research Center in Tianjin.

Beyond presenting robust technical evidence, Nio's preparation team repeatedly emphasized one key point to the expert committee: "The industry needs a pioneering 'demonstration vehicle' that dares to blaze new trails."

"Without mass production, SBW will forever remain confined to the laboratory. Nio is willing to dedicate an 800,000-yuan flagship model to full redundancy design, deploy it on real roads, and accumulate data. Only by generating this data can national standards gain a foundation, and only then can future players find a path forward."

This sincerity, coupled with Nio's submission of forward-looking test reports -- including 10 categories of aviation-grade test reports, 41 stringent testing specifications and acceptance criteria, 10 high-speed fault injection tests, and 9 performance tests -- gradually swayed the review panel.

In November 2024, after countless rounds of validation and negotiations, the Nio ET9 officially passed the MIIT's 388th batch of the "Announcement of Road Motor Vehicle Manufacturers and Products." This was more than just a birth certificate; it signaled that China's automotive industry had broken free from that vicious cycle.

In May 2025, the Nio ET9 SBW system further secured E-Mark certification under the United Nations Economic Commission for Europe (UNECE) automotive regulations. E-Mark is a technical certification system implemented by UNECE member states for vehicles and components, recognized across Europe, Africa, and select markets in Southeast Asia and Oceania. This achievement established the ET9 as the world's first SBW production vehicle to obtain dual market approvals in both China and Europe.

Technology implementation, data feedback. In December 2025, GB 17675-2025 "Basic Requirements for Automotive Steering Systems" was officially released.

This new standard provides the foundational basis for product access and practical application of SBW technology, marking a milestone in regulating and guiding the development of China's automotive steering technology.

Nio served as one of the lead drafting units for this national standard.

During the standard's development, Nio unreservedly shared its "fully redundant" architecture, failure mode analysis, and testing methodologies -- all accumulated during ET9 R&D -- with the drafting group. This contribution provided scientific rationale and data support for the standard's successful completion and future framework.

"Previously, no one dared to do it because they didn't know what constituted compliance. Now, we've paved the way, filled the potholes, and set the road signs," Kevin remarked. His tone carried less of the euphoria of crossing the finish line and more of a sense of relief. "Future Chinese automakers can follow this path to move faster and more steadily."

8. Only "our chassis"

In the world of chassis engineering, there are no miracles -- only the delicate interplay between systems.

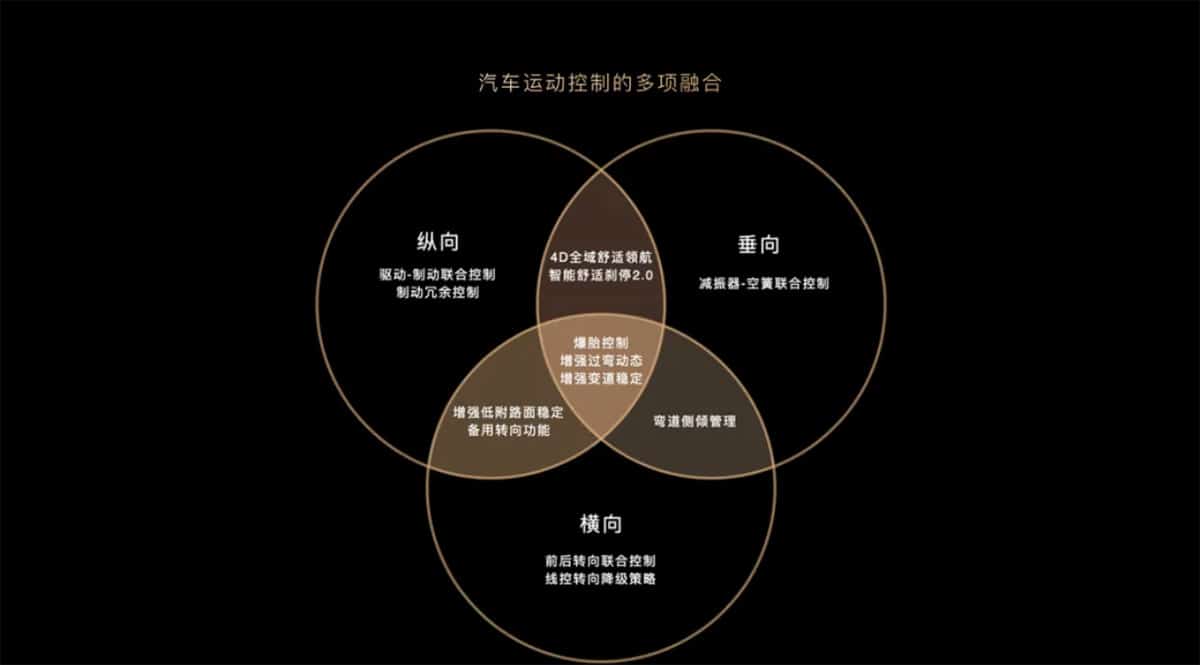

On the ET9, this challenge is amplified exponentially. Full Active Suspension (FAS), Steering-by-Wire (SBW), and Rear-Wheel Steering (RWS) -- when these three most powerful "monsters" in chassis technology are crammed into a single vehicle, all past tuning experience becomes obsolete.

"This is one of the world's production vehicles with the most actuators -- and certainly the undisputed leader in China," admits Dr. Xiao, Head of Vehicle Software Development at Nio.

If each system operated independently, the car would suffer from "split personality." The suspension would seek softness, the steering would demand firmness, and the brakes would crave stability -- ultimately leading to disaster.

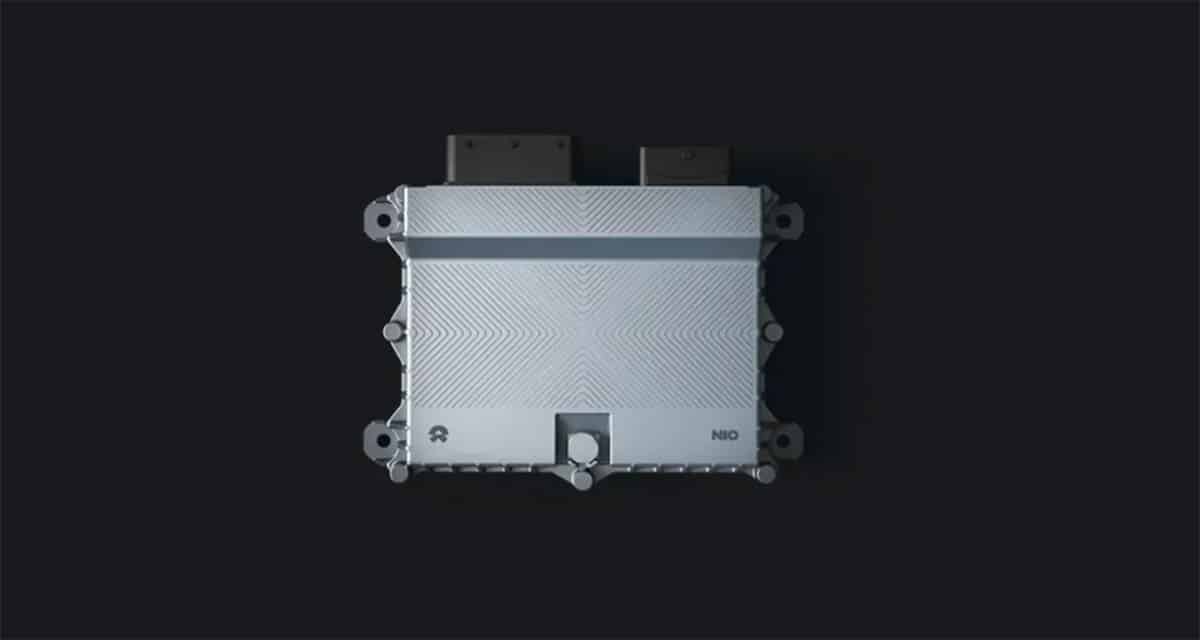

Thus, VMC (Nio's Intelligent Chassis Computing Platform) was born. It emerged from two pressing challenges: First, hardware complexity had surpassed traditional development limits. "Using conventional methods, we'd have to individually tune these six degrees of freedom -- an impossible and ineffective task." Second, advanced smart driving systems demanded it.

"If the smart driving system had to individually call upon five or six controller interfaces -- steering, braking, suspension, and others -- without VMC, it would be a disaster. VMC must become that unified interface, connecting the perception layer of smart driving to the execution layer of the chassis."

As Dr. Xiao puts it: VMC is like a symphony conductor: absorbing conflicts among all 'voices,' reorganizing, coordinating, and predicting them, ultimately weaving them into a melody with audible rhythm and perceptible direction."

VMC's core value isn't "speed," but "judgment." This value is vividly demonstrated in the "high-speed blowout" scenario that makes every engineer's scalp tingle.

Within the industry, there was once an unspoken consensus: tire blowouts exceeding 120 km/h were deemed "uncontrollable." "Previously, when researching blowouts, everyone stopped studying them beyond 120 km/h -- theoretically uncontrollable," Dr. Xiao explained. But on the ET9, Nio engineers pushed test speeds up to 170 km/h. The moment sensors detected a blowout signal, VMC instantly executed a series of complex decisions at this critical juncture:

Step 1: Diagnosis. Confirming it was a blowout -- not a deliberate lane change by the driver -- VMC immediately suppressed erroneous steering inputs caused by the driver's panic.

Step 2: Dispatch: Within 300 milliseconds, it simultaneously issued commands to dozens of actuators throughout the vehicle.

Step 3: Execute: SBW and the rear-wheel steering system engaged within 230 milliseconds. ESP immediately adjusted torque distribution, while the fully active suspension rapidly corrected vehicle posture to prevent center-of-gravity shift.

Simultaneously, the driver assistance system activates emergency response. Even if the driver fails to react in time, the vehicle maintains assisted driving capability. Instead, the system autonomously completes the entire process: lane change, pulling over, stopping, and even initiating emergency assistance.

This capability is underpinned by Nio's in-house developed expertise, cultivated since the ICC (Intelligent Chassis Domain Controller) era. The VMC, built on the "SkyOS" operating system, achieves true software-hardware decoupling.

It interfaces with the perception layer of smart driving assistance above and connects to the chassis execution layer below, transforming the chassis from a mechanical entity into an intelligent agent with a "brain." From VMC's development to its mass production implementation in the ET9 took less than two years.

To train this "brain," the team conducted massive virtual validation through software-in-the-loop (SIL) and hardware-in-the-loop (HIL) simulations before the actual vehicle rolled off the production line, rehearsing thousands of possible system coordination scenarios.

When the first ET9 prototype vehicle (mule car) finally hit the road, the test engineers were pleasantly surprised: it actually handled quite smoothly.

VMC broke through the physical isolation of hardware components. In the real world, it also forced Nio to break down organizational silos. "FAS, SBW, rear-wheel steering, braking, and electric drive -- no one can just focus on their own domain. To make them work together, we had to break up the teams and rebuild them."

Many OEMs are accustomed to "interface-based collaboration": the suspension team handles suspension, the steering supplier manages steering, and everything is cobbled together at the last minute by domain controllers. But at the technical level of the ET9, this "patchwork" approach simply doesn't work.

So Nio made a difficult but highly effective decision: to merge software and hardware engineers and other relevant teams into a true special forces unit.

At the Anting test track in Shanghai or the ice fields of Mohe, you'd often witness this scene: a camouflaged vehicle packed with people in the backseat.

Suspension engineers explaining feedforward logic to braking specialists; steering engineers discussing torque input with powertrain teams; VMC algorithm engineers scrutinizing the same curve alongside NVH engineers.

There is no longer "your system" or "my system" -- only "our chassis."

9. The "time difference" from China

May 2025, Munich, Germany.

An international automotive technology symposium -- recognized as the industry's premier event -- was underway. Dr. Xiao sat in the audience as a technical director from a German luxury automaker presented their future chassis domain controller concept on stage.

He turned to his Chinese colleague and remarked with a meaningful look: "Isn't this exactly what we presented at ICC two or three years ago?"

In that moment, a subtle "time lag" became palpable. For Dr. Xiao, this feeling was profoundly resonant, as he had once been part of that "old world."

Dr. Xiao had studied and worked in the UK for over a decade, previously employed at the European R&D center of an American automaker. That was the heartland of traditional automotive industry, boasting the most advanced technological foundations. Yet he felt a deep sense of anxiety.

"Personally, I felt the pace was too slow. While overseas technical research was highly advanced, product iterations followed a 4-5 year cycle. It was essentially a state of coasting on technological dividends."

At the April 2017 Shanghai auto show, Dr. Xiao returned to China. There, he saw the first-generation ES8 at Nio's booth. Though it was merely a concept car at the time, he was profoundly impressed.

"My first thought was, 'Can a Chinese company really produce something like this?'" That chance encounter led him to leave his comfortable life in Europe and join this then-uncertain Chinese startup. Three years later, he led his team from developing the ICC to the current VMC, making European peers feel the "time difference" coming from China.

"It's now clear we've gained a half-step lead in chassis development," Dr. Xiao said.

This "half-step" advantage may not stem solely from in-house developed technology, but rather from the engineers' attitude toward driving itself.

If you encounter members of the chassis team at Nio's campus, you'd struggle to pin them down with a single label.

But after just three minutes of conversation, one common thread emerges: they are passionate about driving -- so much so that they treat it as a skill, a language, and even a habitual way of thinking.

Some joke that "Nio's chassis tuning isn't the work of one or two experts, but a team of engineers who treat driving as a passion. Through daily dynamic validation, they transform preferences into parameters, experience into models, and intuition into precise control logic."

This statement sounds undersaid, yet it reveals the most crucial secret behind Nio's decade-long chassis development.

Starting from a blank slate in 2014, Nio broke through with ICC, then surged ahead globally with the ET9's fully electronic chassis. Building upon three decades of accumulated achievements in China's automotive industry, Nio traversed an uncharted path in just ten years. It was an exceptionally solitary journey.

While the industry was racing to innovate in visible areas like TVs and refrigerators, Nio chose to invest its greatest human and financial resources into the unseen realm of chassis engineering.

Why?

William Li once defined the "new three core components" of smart vehicle technology: smart driving assistance chips, vehicle-wide operating systems, and smart chassis. These three elements determine the upper limits of both user experience and safety in smart vehicles.

The chassis isn't the most flashy technology. It lacks the "sex appeal" of large models or the visual impact of LiDAR. Yet in the era of smart vehicles, the chassis is becoming the foundation for advanced smart driving assistance.

Looking back at that late-night email from 2018, the William Li of that time likely never imagined that the agonizing questions about the "black box" would eventually spark a sweeping technological revolution.

Today, at Nio's R&D center, engineers who love driving itself -- those who stay up late in the backseat of test vehicles -- still passionately debate over a single parameter.

They no longer need to look up to foreign suppliers, because the chassis beneath their feet -- the Skywalk fully electronic chassis -- stands as one of the most advanced chassis of this era.

The rollout of Nio's 1-millionth production vehicle is merely the beginning. Behind these million cars lies the Chinese automotive industry finally cracking that decades-old "black box" -- achieving a magnificent transformation from follower to leader in the most obscure and hardcore realm of chassis technology.

The story continues, but the rules have already been rewritten.

Update: Fixed a typo.