- The alloy technology will be open to the entire industry to drive the adoption of high-pressure casting technology with better performance and cost-effectiveness, Nio said.

- It is the first self-hardening aluminum alloy for structural large castings developed by a Chinese automotive brand, breaking the monopoly of C611.

Nio (NYSE: NIO) announced the development of a new aluminum alloy material as part of its technology portfolio.

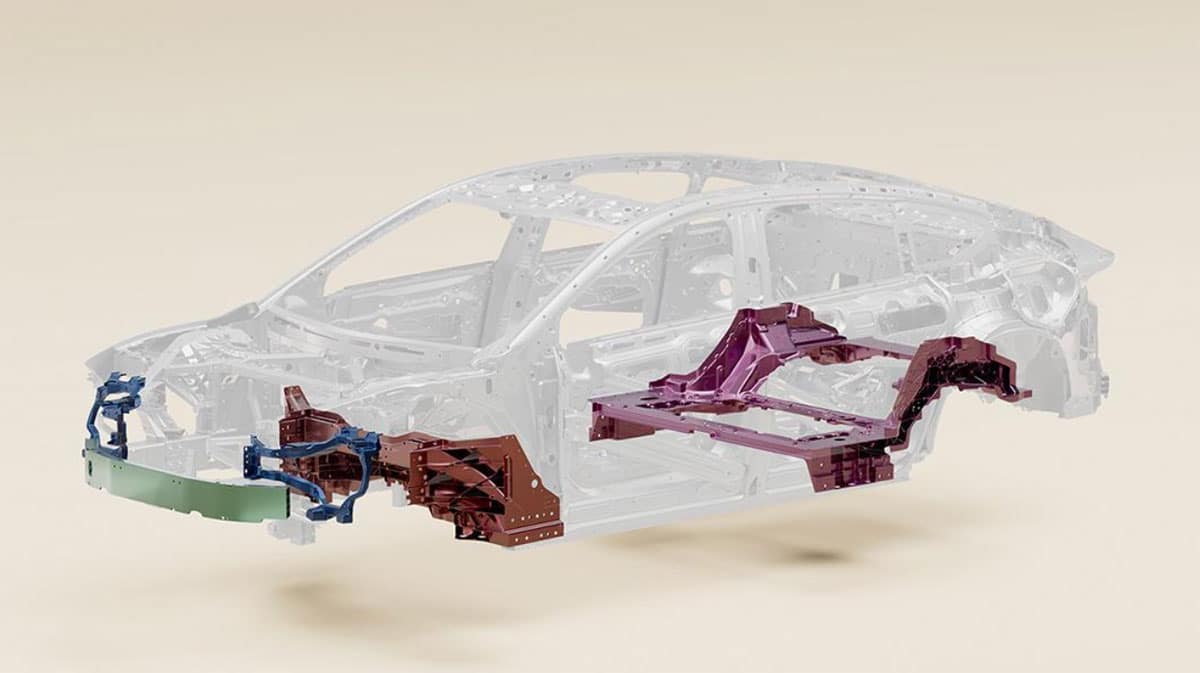

The electric vehicle (EV) maker says the material is a self-hardening new alloy for high-pressure die casting (HPDC) and has already been used in the body-in-white of the Nio ET9 and Onvo L60.

The ET9 was launched in December last year at a starting price of RMB 788,000 ($108,000), including the battery pack, making it Nio's most expensive to date.

The L60, the first model from sub-brand Onvo, starts at RMB 206,900 including the battery pack.

The alloy technology will be open to the entire industry, with better performance and cost-effectiveness driving the adoption of high-pressure die casting, Nio said in a post on its mobile app.

This is the first self-hardening aluminum alloy for structural large castings developed by a Chinese automotive brand, breaking the monopoly of C611 aluminum alloy in China's large die casting market, the company said.

It has also achieved breakthroughs in terms of economic, environmental and intellectual property benefits, and leads to a wave of research and development of heat-treatment-free die-cast aluminum alloys for China's automotive industry, Nio said.

The material was developed and validated by Nio's Materials Research and Applications (MRA) laboratory team.

The team collaborated with multiple other teams, including Nio's design, manufacturing and industrialization, to conduct multiple levels of validation prior to mass production.

After balancing cost and performance, Nio released the new alloy to the vehicle program, said Gary Hughes, the MRA team leader.

The new alloy is based on an aluminum-silicon alloy system that was carefully tuned chemically and underwent multiple trial runs in the die-casting shop, according to Liu Huachu, MRA team principal researcher.

Nio's efforts proved the material is suitable for making large, mega castings for parts such as rear floors and battery casings, according to Liu.

In the development of the material, Nio was supported by partners including alloy maker CSMET, high-pressure casting vendor Wencan and Huihan, according to the company.

($1 = RMB 7.2975)