Tesla China's payment cycle to supply chain partners has been further shortened to around 90 days from about 101 days in 2023, according to Tesla VP Grace Tao.

Tesla (NASDAQ: TSLA) is seen as a carmaker that is relatively friendly financially for its supplier partners, and that has improved further this year.

In 2024, Tesla China's payment cycle to supply chain partners has been shortened again from last year, and now only takes about 90 days, Tesla's vice president of external affairs, Grace Tao, said in a Weibo post today.

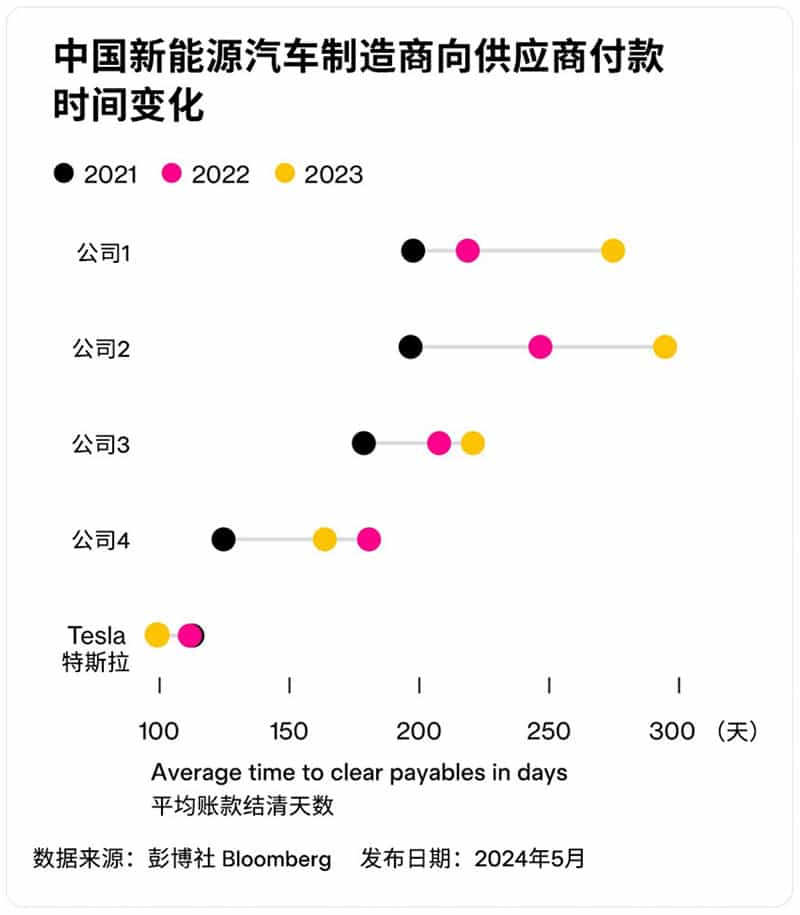

A chart she attached to her Weibo shows that Tesla's time for paying suppliers in 2023 were about 100 days, while four other unnamed new energy vehicle (NEV) makers were all over 150 days.

The chart is based on one from a Bloomberg report published in May of this year.

In the May 20 report, Bloomberg said Nio (NYSE: NIO) was taking around 295 days to clear its receipts payable at the end of 2023, up from 197 days in 2021.

Xpeng (NYSE: XPEV) needed 221 days to fulfill its obligations to suppliers and related parties, up from 179 days in 2021, according to that May report.

BYD (HKG: 1211, OTCMKTS: BYDDY) was at 275 days at the end of 2023, up from 198 days in 2021, according to the report.

By comparison, Tesla only took about 101 days, and that time has remained largely stable over the past three years, the report said.

More than 95 percent of Giga Shanghai's components come from local suppliers, and what Tesla has accomplished in China and around the world is closely tied to those partners, Tao said today, repeating the previously mentioned number.

A company can only go further with its supplier partners and through technological innovation to increase efficiency and reduce costs, she said.

Only then will the industry prosper and consumers continue to get the best products, Tao said.

Tao's Weibo seems aimed at comparing Tesla China to local players including BYD (HKG: 1211, OTCMKTS: BYDDY) and SAIC Motor, at a time when they are demanding price cuts from suppliers.

A leaked letter yesterday showed BYD asking some of its suppliers of passenger car products to cut prices by 10 percent from January 1, 2025, on the products they supply.

After the letter sparked widespread discussion, Li Yunfei, BYD's general manager of branding and public relations, said in a Weibo post that annual bargaining with suppliers is a customary practice in the auto industry and is not mandatory.

Later yesterday, China Securities Journal, citing documents obtained from auto supply chain sources, reported that SAIC Maxus, a subsidiary of SAIC Motor, also sent a letter to its suppliers on November 25, setting a target of reducing parts costs by 10 percent.

In the automotive industry, where such situations are common, suppliers can only do what they can to expand to as many customers as possible and spread the risk, Tencent News said in a report yesterday, citing an industry source.