That's because Svolt's operations in its home market in China are already struggling, and it can't afford to handle overseas factories that require a lot of capital, according to Caixin.

Svolt Energy, a battery maker that was spun off from Great Wall Motor (HKG: 2333), has suspended its two battery factory projects in Germany and has no timetable for resuming work, local media outlet Caixin said in a report yesterday, citing several people familiar with the matter.

Svolt had planned to build two factories in Germany, a battery module and pack plant in Saarland and a cell plant in Brandenburg, the report noted.

The pack project, for which plans were announced in November 2020, was originally expected to be completed by mid-2024, with a design capacity of 24 GWh and a total investment of €2 billion.

Construction plans for the cell plant were announced in September 2022, with an annual capacity of 16 GWh. This is Svolt's first overseas cell plant, which was originally planned to become operational in 2025, but construction has been suspended in the middle of this year, according to Caixin.

Construction of both plants is currently at a standstill with no timetable, the report said, citing multiple market sources close to Svolt.

That's because Svolt is already struggling to operate in its domestic market in China, and it can't afford to handle overseas factories, a person familiar with the matter said.

To be built, the two European plants would require an investment of RMB 30 billion yuan, which is too much for a lithium battery maker of Svolt's size, the person said.

The decision was made by Svolt based on its own situation, not technical or local policy factors, and mainly because of the scale of the upfront capital investment, another person familiar with the matter said, adding that Svolt has to solve the money problem first.

Svolt, which became independent from Great Wall Motor in February 2018, focuses on battery materials, cells, modules, packs, BMS, and energy storage technology.

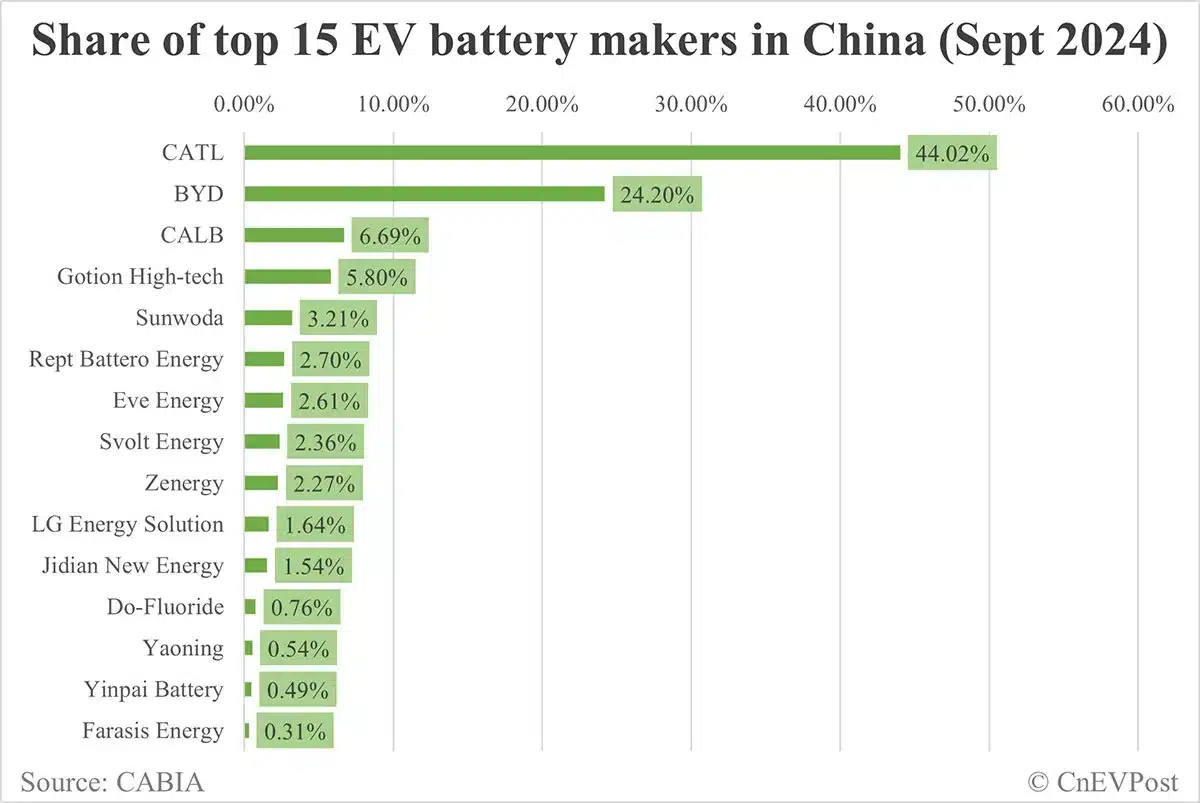

It is one of the largest battery makers in China, with 1.29 GWh of batteries loaded in September, and ranked No. 8 in the domestic power battery market with a 2.36 percent share, according to China Automotive Battery Innovation Alliance (CABIA).

Contemporary Amperex Technology Co Ltd (CATL, SHE: 300750) and BYD (HKG: 1211, OTCMKTS: BYDDY) dominated the market, with shares of 44.02 percent and 24.20 percent respectively in September.

Exports currently account for roughly 20 percent of Svolt's capacity, but overseas orders come mainly from Great Wall Motor, Caixin's report noted.

Taking into account that some of the batteries are loaded in China before being exported, Svolt's actual capacity for exports is less than 20 percent, the report said.

Chinese power battery prices have seen a sharp decline over the past two years as growth in the new energy vehicle (NEV) sector has slowed and raw material prices, such as lithium carbonate, have fallen.

Smaller battery makers originally relied on low prices to gain customers, but leading players, including CATL, are no longer as assertive as they used to be amid fierce competition.

In February, Svolt chairman and CEO Yang Hongxin said on Weibo that the company had initiated deep changes since January in response to overcapacity and price competition in the industry, including increased elimination of poorly performing employees.

In addition to Svolt, Great Wall Motor itself is scaling back its operations in Europe.

Great Wall Motor planned to close its European headquarters in Munich at the end of August and fire all of its roughly 100 local employees, German media outlet Manager Magazin said in a May 28 story.

According to the Caixin report yesterday, Great Wall Motor adjusted its European business strategy in June, closing its German office and laying off all of its employees, and taking back management of its European dealerships and customers.