Tesla's latest electric drive system is the Performance 4DU for the 2024 Model 3 Performance, claiming a 32 percent peak power increase over its predecessor.

Tesla's (NASDAQ: TSLA) 10 millionth electric drive system in its history rolled off the assembly line at its Shanghai factory, the first of the US electric vehicle (EV) maker's in-house components to reach the milestone.

Tesla announced the milestone on Weibo last night, saying it had redefined the electric drive system and produced it in-house from scratch.

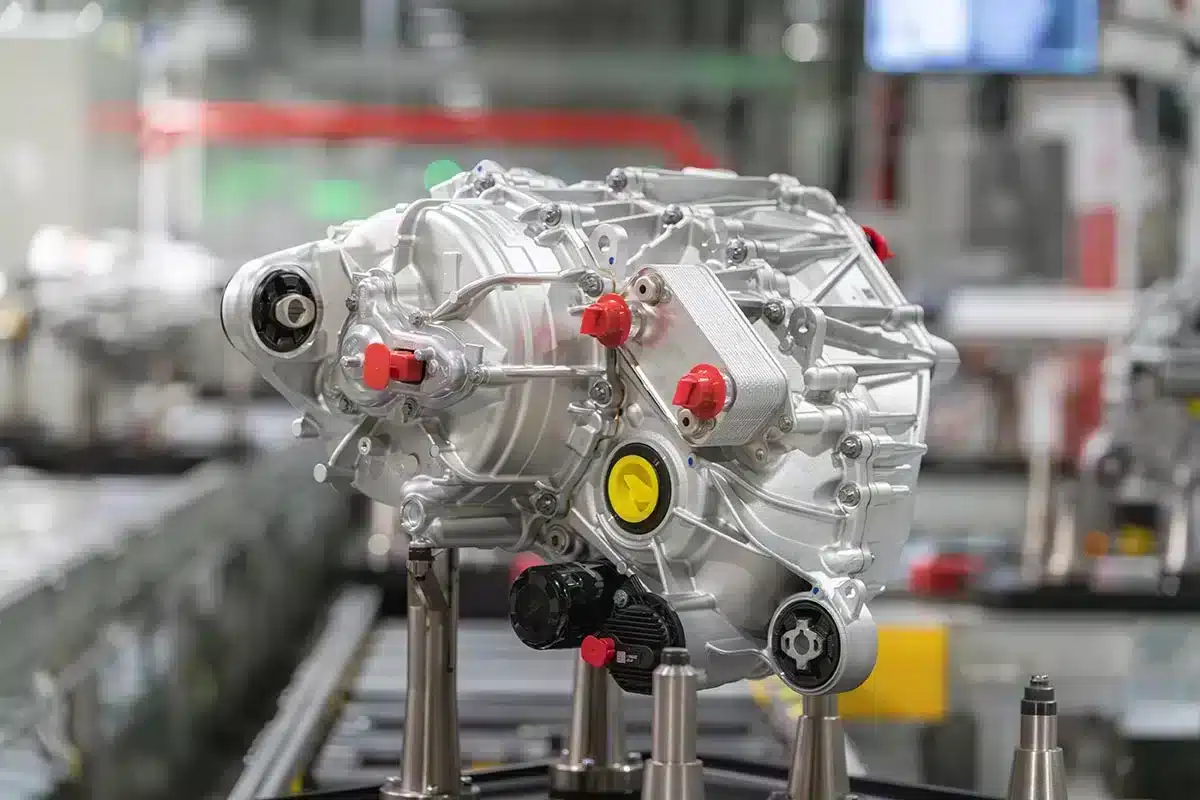

The electric drive system, which includes the motor, gearbox, and motor controller, is the heart of an EV and determines the core experience of the vehicle, Tesla said.

“More than 10 million powerful 'hearts' make Tesla models performance cars,” the EV maker wrote in Chinese on Weibo.

“Thanks to the support and companionship of more than 6 million vehicle owners, together we are accelerating the world's transition to sustainable energy,” Tesla said.

Tesla's first-generation electric drive system was used in the Roadster, and they had very few deliveries. The second-generation electric drive system was used in the Model S and Model X, and the third-generation electric drive system, which featured permanent magnet synchronous motors for the first time, was used in the Model 3 and Model Y.

Now, Tesla's electric drive system costs less than half as much as the electric drive system in the first-generation Model S, according to a video it posted on Weibo.

Tesla's latest electric drive system is the Performance 4DU for the 2024 Model 3 Performance, and here's how it's described on Tesla's website:

Our latest generation performance drive unit – Performance 4DU – unlocks more torque, power and better efficiency.

Compared to the previous Model 3 Performance drive unit, the Performance 4DU can deliver up to +22% continuous power, +32% peak power, and +16% peak torque delivery.

Behind the wheel, drivers will sense more immediate and sustained acceleration out of corners. That’s the beauty of more torque!

Tesla's Shanghai factory, which began construction on January 7, 2019 and became operational by the end of 2019, is the first wholly foreign-owned automotive manufacturing project in China.

Giga Shanghai began delivering Model 3 to local consumers in January 2020 and Model Y in January 2021.

On August 13, 2022, Giga Shanghai saw the one millionth mass-produced vehicle built here roll off the line, less than three years after production began at the plant.

On September 6, 2023, the plant saw the two millionth vehicle it produced roll off the line.

On September 18, 2023, Tesla announced that its 5 millionth vehicle worldwide rolled off the line at Giga Shanghai.