Volvo Cars announced yesterday that it will invest $1.1 billion in upgrades to its plant in Sweden, a key one of which is the introduction of a large casting process.

(Image credit: Volvo Cars)

Volvo Cars is the first major carmaker after Tesla to publicly announce that it will use the giant integrated die-casting technology, and now the company is reportedly bringing it to China.

Volvo has plans to bring the aluminum alloy one-piece casting process and battery cell to chassis (CTC) technology to its Chinese plants, local media Cailian said today, citing sources familiar with the matter.

Volvo became the first Chinese-owned luxury car brand when Geely Group bought 100 percent of its shares in August 2010. Volvo now has three factories in China.

Volvo will use an 8,000-ton integrated casting machine, the same as the GigaPress rumored to be used for Tesla's Cybertruck, and higher than the 6,000-ton machine currently used by Tesla for the Model Y.

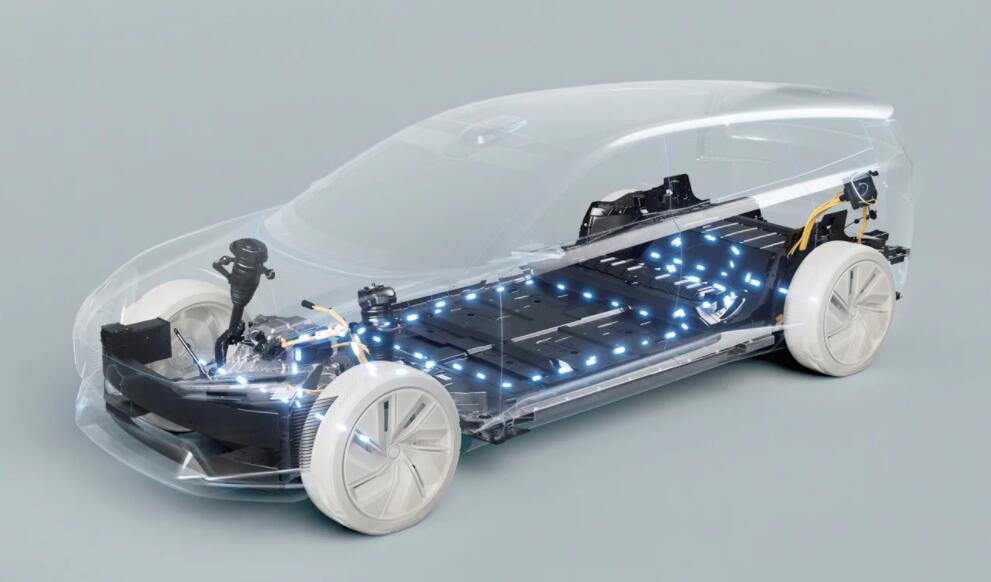

Volvo will also build a new battery assembly plant to integrate battery cells and modules into the car's chassis structure, the company said yesterday.

Volvo will die-cast the rear of the chassis with an 8000T integrated casting machine, highly flexible while reducing the complexity of production, according to an interview with Mikael Fermér, head of Volvo's vehicle platform architecture, published today by tech media Geekcar.

Volvo, one of the first automakers to invest in the innovative process of integrated casting technology, did not jump the gun and took the time to work out the process difficulties one by one, according to Fermér.

Large-scale integrated die-casting technology is seen as the key to improving efficiency for electric vehicle companies, and Nio and Xpeng Motors are also expected to be the latest car companies to adopt the technology.

Shenzhen-listed auto parts supplier Guangdong Hongtu Technology held a signing ceremony on January 22 to launch a 6,800-ton chassis integrated structural part and a 12,000-ton super die-casting unit partnership.

Executives from several automotive companies, including Zeng Shuxiang, CEO of Nio's motor division XPT, congratulated the event in a recorded video at the time.

Xpeng Vice President Jiang Ping was on hand for the event and gave a speech, saying that the event was another milestone event for Guangdong Hongtu as it took a big step forward in the one-piece die-casting field.

There is no information yet on whether Nio and Xpeng will use Guangdong Hongtu's large die-casting machines. But Hongtu had said last year that it was already in the supply chain of Nio and Xpeng, without providing further details.