Nio, Xpeng's supplier Guangdong Hongtu saw the 6,800-ton integrated die-casting machine come off the production line and started developing a 12,000-ton die-casting unit.

Large-scale integrated die-casting technology is seen as the key to improving efficiency for electric vehicle makers, and Nio and Xpeng Motors are expected to be the latest to adopt the technology.

Shenzhen-listed auto parts supplier Guangdong Hongtu Technology said in an announcement today that it held a signing ceremony on January 22 for the launch of 6,800-ton chassis integrated structural parts and a partnership for a 12,000-ton super die-casting unit.

The company will work with partners including die-casting machine maker L.K. Technology to develop the 12,000-ton die-casting unit, according to the announcement.

Guangdong Hongtu has entered into an intentional agreement with a Shenzhen-based subsidiary of L.K. Technology to purchase eight large and super die-casting units, the announcement said.

The announcement provided no further details, but executives from several vehicle companies, including Zeng Shuxiang, CEO of Nio's motor division XPT, congratulated the event in a recorded video, according to a live replay of the event from Guangdong Hongtu.

(Zeng Shuxiang, CEO of Nio's motor division XPT, congratulated Guangdong Hongtu on the event in a recorded video.)

Xpeng vice president Jiang Ping was present at the event and gave a speech, saying that the event was a major step forward for Guangdong Hongtu in the field of one-piece die-casting and another milestone event in the field.

(Xpeng vice president Jiang Ping gave a speech at Guangdong Hongtu's event.)

There is no information yet on whether Nio and Xpeng will use Guangdong Hongtu's large die-casting machines. But Hongtu had said last year that it had entered the supply chain system of Nio and Xpeng, without providing more details.

If Nio and Xpeng adopt the large die-casting machine, then their manufacturing process is expectd to be upgraded to a higher level.

Tesla currently uses a 6,000-ton integrated die-casting machine in the production of the Model Y. Previous media reports said the company will use an 8,000-ton integrated die-casting machine for Cybertruck.

Compared with the traditional body manufacturing stamping and welding process, one-piece die-casting can help reduce the weight of the model, reduce the number of parts and process steps, thus saving costs significantly.

Previous media reports have suggested that six Chinese automakers are already planning to use a large die-casting facility similar to Tesla.

Although Nio has not officially confirmed that it will use large die-casting equipment, its previous efforts are already paving the way for this.

On October 18 last year, Nio announced that it had successfully validated the development of a heat-treatment-free material that could be used to make large die castings.

This is the first of its kind for a Chinese carmaker, and the new material will be used in models built on its second-generation platform, according to Nio.

On December 18 last year, Nio announced the ET5 sedan. When asked by CnEVPost in an interview on December 19 whether Nio has plans to introduce large die-casting machines in its production line, William Li, founder, chairman and CEO of Nio, did not give a direct answer, but revealed interesting information.

"We are using an integrated die-casting process for the rear subframe of the ET5," Li said.

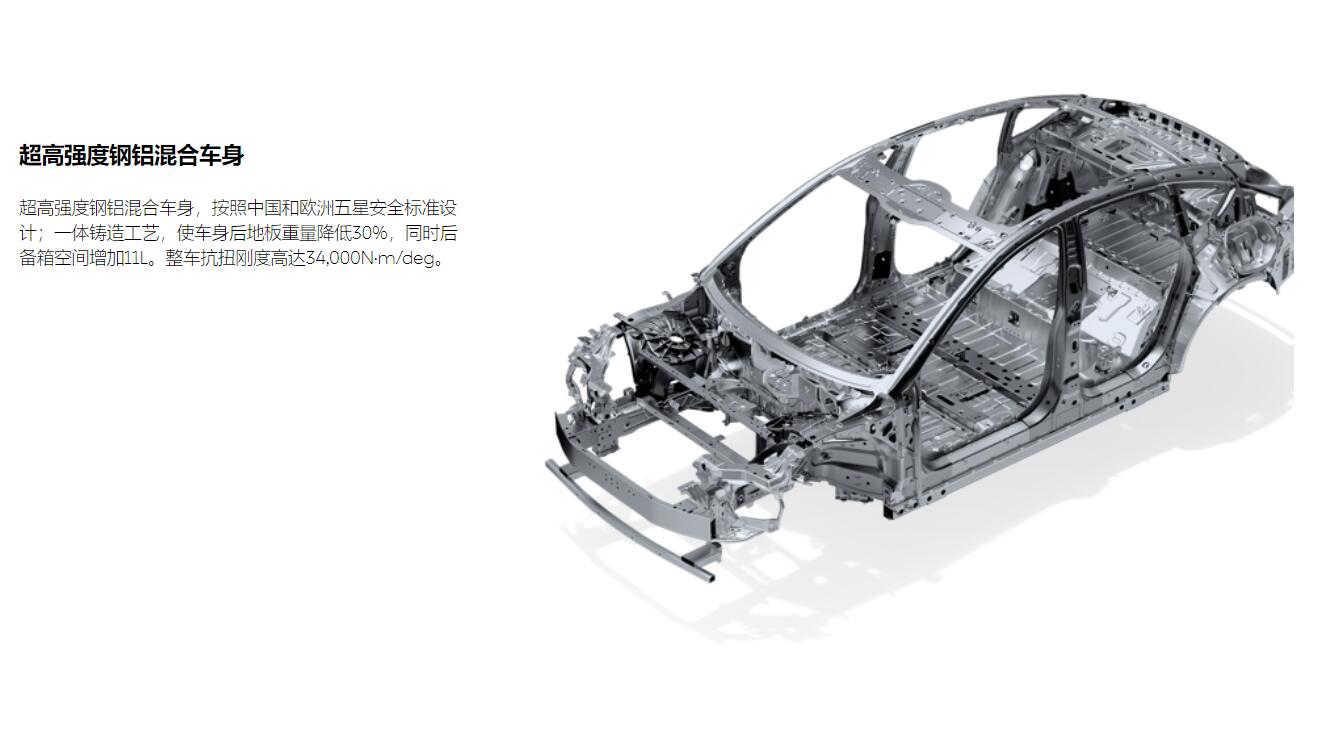

(Screenshot from Nio's website about ET5.)

CnEVPost then found, when checking the ET5's technical specifications, that the ET5's rear subframe uses a so-called integrated hollow cast aluminum process.

Compared to the all-steel welded process, the technology allows for a guaranteed strength increase from 31kNm/deg to 34kNm/deg, while reducing weight by 13kg and allowing for 11L more trunk space, according to Nio.